Table of Contents

ToggleThe Accidental Discovery That Changed Science

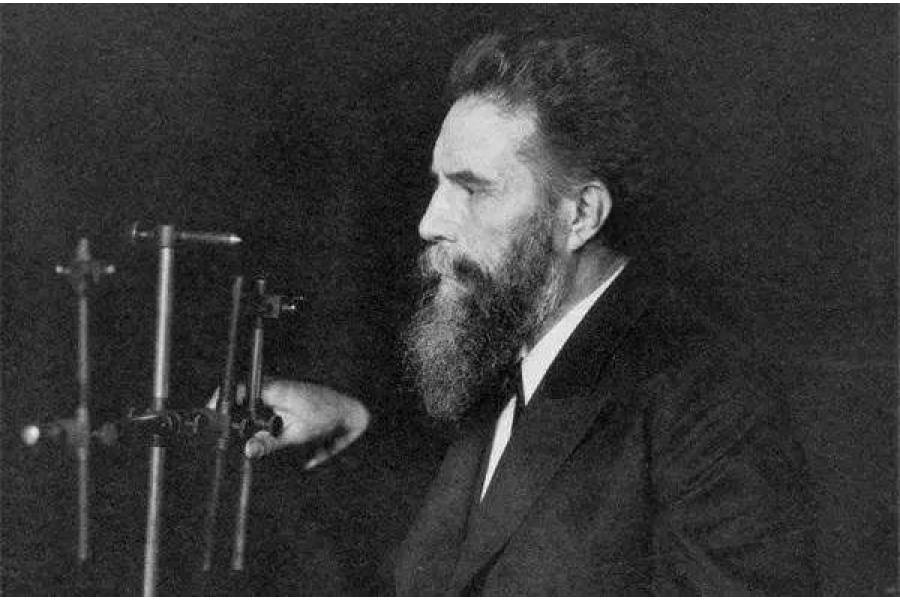

In the late 19th century, the field of physics was rapidly advancing, with scientists exploring new frontiers and pushing the boundaries of knowledge. It was in this climate of scientific curiosity that a German physicist named Wilhelm Röntgen made an accidental yet groundbreaking discovery that would forever change the course of medicine, manufacturing, and security. On November 8, 1895, while experimenting with cathode ray tubes in his laboratory at the University of Würzburg, Röntgen noticed an unexpected and peculiar phenomenon – a fluorescent glow emanating from a nearby chemically coated screen, despite it not being directly exposed to the cathode rays. This odd occurrence piqued Röntgen’s curiosity, leading him to systematically investigate the cause of this mysterious glow.

Investigating the Unknown

Undeterred by the initial uncertainty surrounding this new type of radiation, Röntgen embarked on a series of methodical experiments to unravel its properties and behavior. He temporarily termed these rays “X-radiation” due to their unknown nature at the time. Through careful observation and testing, Röntgen discovered that these X-rays possessed the remarkable ability to pass through human flesh but were blocked by denser materials like bone or metal. This realization opened up a world of possibilities for medical diagnosis and non-destructive testing.

The First Radiographic Image

In one of his most famous and iconic experiments, Röntgen captured the first radiographic image by placing his wife’s hand on a photographic plate and exposing it to the X-rays. The resulting image, now known as “Hand with Rings,” revealed the skeletal structure of her hand surrounded by the lighter shadows of her flesh. This groundbreaking image not only marked the beginning of a new era in medical imaging but also demonstrated the incredible potential of X-rays to visualize the internal structures of the human body without invasive procedures.

Properties of X-Rays

As Röntgen delved deeper into his studies, he meticulously documented several key properties of X-rays that would shape their future applications. He discovered that X-rays travel in straight lines and can penetrate varying thicknesses of solid matter, with their penetration depth depending on the density of the material. Additionally, he found that X-rays are produced by the bombardment of a metal target by high-energy electrons in a vacuum tube, a process that would later become the basis for modern X-ray machines. Röntgen also observed that X-rays cause certain fluorescent materials to glow, making them visible to the human eye, and that they can ionize gases, making them electrically conductive. Perhaps most significantly, he realized that X-rays can affect photographic plates, enabling the creation of radiographic images – a discovery that would revolutionize medical diagnostics.

Impact on Medicine

The impact of Röntgen’s discovery on the field of medicine was immediate and profound. Doctors and medical professionals could now see inside the human body without the need for invasive surgery, opening up new avenues for diagnosis and treatment. X-ray imaging allowed physicians to detect fractures, locate foreign objects, and identify diseases like tuberculosis or cancer at early stages, significantly improving patient outcomes. The ability to visualize internal structures non-invasively was a game-changer in the medical field, and X-ray technology quickly became an indispensable tool in hospitals and clinics around the world.

Application in Manufacturing

While the medical implications of Röntgen’s discovery were groundbreaking, the ability to “see” inside solid objects also opened up new possibilities in manufacturing and quality control. X-ray inspection machines and parts counters became invaluable tools for detecting defects, verifying the integrity of components, and ensuring product safety. By subjecting manufactured parts and assemblies to X-ray examination, manufacturers could identify internal flaws, voids, or inclusions that would otherwise be invisible to the naked eye. This non-destructive testing method allowed for quality control without compromising the integrity of the final product, leading to improved reliability and safety standards across various industries.

Security and Safety Measures

The penetrating nature of X-rays also found applications in security screening, as airports and other high-security facilities began using X-ray scanners to inspect luggage and cargo for potential threats. By detecting concealed items or materials based on their density and composition, X-ray scanners became a crucial tool in maintaining public safety and preventing security breaches. However, as the potential health risks associated with X-ray exposure became better understood, strict safety protocols and shielding measures were implemented to protect both operators and the general public from excessive radiation exposure.

Evolution of X-Ray Technology

Since Röntgen’s pioneering work, X-ray technology has undergone significant advancements and refinements. Modern X-ray machines are more powerful, precise, and safer than their early counterparts, thanks to ongoing research and technological innovation. Digital imaging systems have replaced traditional photographic plates, enabling faster and more efficient image acquisition and processing. Additionally, computed tomography (CT) scanners, which combine multiple X-ray projections to create detailed cross-sectional images, have further enhanced the diagnostic capabilities of X-rays in medical settings.

Beyond medical applications, specialized techniques like X-ray fluorescence (XRF) and X-ray diffraction (XRD) have found widespread use in material analysis and crystallography. XRF allows for the identification and quantification of elements in a sample based on their characteristic X-ray emission spectra, while XRD provides insights into the atomic and molecular structure of crystalline materials. These advanced applications have expanded the reach of X-ray technology into fields such as archaeology, forensics, and advanced materials research.

The Nobel Prize and Lasting Legacy

In recognition of his groundbreaking discovery and its immense impact on science and society, Wilhelm Röntgen was awarded the first Nobel Prize in Physics in 1901. His name has become synonymous with the X-rays he discovered, and his work continues to shape numerous fields, from medicine and manufacturing to security and scientific research. Röntgen’s accidental discovery and his subsequent exploration of X-rays serve as a testament to the power of scientific curiosity and the importance of systematically investigating unexpected phenomena. His legacy lives on in every X-ray machine, CT scanner, and advanced imaging technology that continues to transform our understanding of the world around us.

Questions and Answers

What is the significance of Röntgen’s discovery?

Röntgen’s discovery of X-rays revolutionized medical imaging by allowing doctors to visualize the internal structures of the human body non-invasively. It also enabled non-destructive testing in manufacturing, ensuring product quality and safety. Furthermore, X-ray technology paved the way for advanced security screening techniques, enhancing public safety and security measures. Overall, Röntgen’s discovery had a profound and lasting impact across various fields, from medicine and manufacturing to security and scientific research.How did Röntgen first observe X-rays?

Röntgen’s initial observation of X-rays was purely accidental. While experimenting with cathode ray tubes in his laboratory at the University of Würzburg, he noticed an unexpected fluorescent glow coming from a nearby chemically coated screen, despite it not being directly exposed to the cathode rays. This peculiar phenomenon sparked Röntgen’s curiosity and prompted him to systematically investigate the cause of this mysterious glow, ultimately leading to his groundbreaking discovery.What properties of X-rays did Röntgen discover?

Through his meticulous experiments, Röntgen discovered several key properties of X-rays. He found that X-rays travel in straight lines and can penetrate varying thicknesses of solid matter, with their penetration depth depending on the density of the material. Additionally, he discovered that X-rays are produced by the bombardment of a metal target by high-energy electrons in a vacuum tube, and that they cause certain fluorescent materials to glow and can ionize gases, making them electrically conductive. Perhaps most significantly, Röntgen realized that X-rays can affect photographic plates, enabling the creation of radiographic images – a discovery that laid the foundation for modern medical imaging and non-destructive testing.How did X-rays impact the field of medicine?

Röntgen’s discovery of X-rays had a profound and immediate impact on the field of medicine. For the first time, doctors and medical professionals could see inside the human body without the need for invasive surgery. X-ray imaging allowed them to detect fractures, locate foreign objects, and identify diseases like tuberculosis or cancer at early stages, significantly improving patient outcomes. The ability to visualize internal structures non-invasively was a game-changer in medical diagnostics and treatment, and X-ray technology quickly became an indispensable tool in hospitals and clinics worldwide.What are some modern applications of X-ray technology?

In the modern era, X-ray technology has evolved and diversified into various applications beyond medical imaging. Digital imaging systems and computed tomography (CT) scanners have further enhanced the diagnostic capabilities of X-rays in medical settings. Specialized techniques like X-ray fluorescence (XRF) and X-ray diff