ISO Certified | Compliant With Local Radiation Safety Policy

Powerful and Safe-to-use X-Ray Inspection System

- High resolution imaging

- High accurate and efficiency

- Non-destructive testing

- ISO 9001

- CE / ROHS

- X-Ray Radiation Level ≤1μSv/h

X-Ray Inspection System Products

Wellman design and manufacturer x-ray inspection systems for a wide range of industrial applications. With years of experience in the x-ray inspection industry, Wellman has developed a reputation for providing high-quality, reliable systems that help ensure the safety and quality of products in industries such as electronics, batteries, semiconductors, and more.

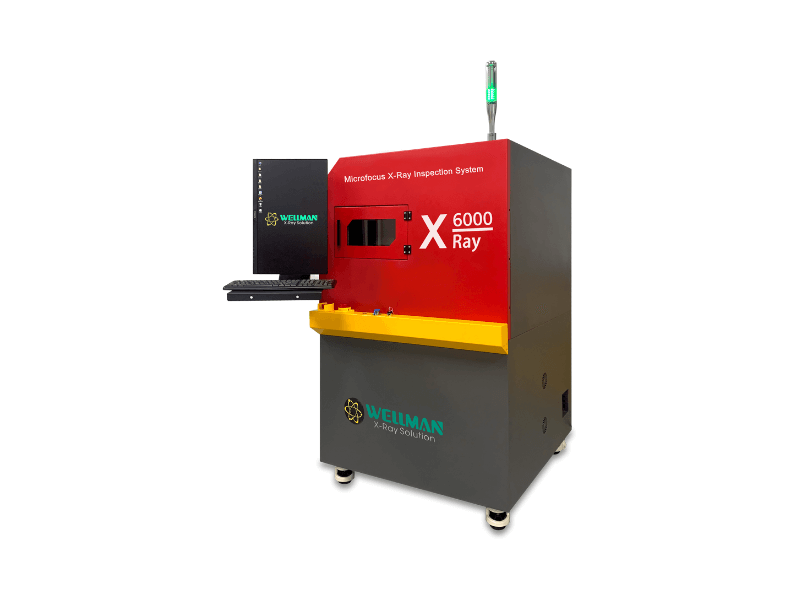

X6000 X-Ray Inspection System

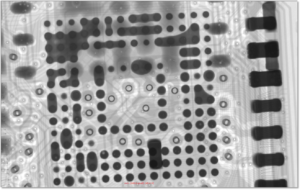

X-ray inspection systems are used to inspect printed circuit boards (PCBs), connectors, and other electronic components for defects such as broken solder joints, cracks, or voids.

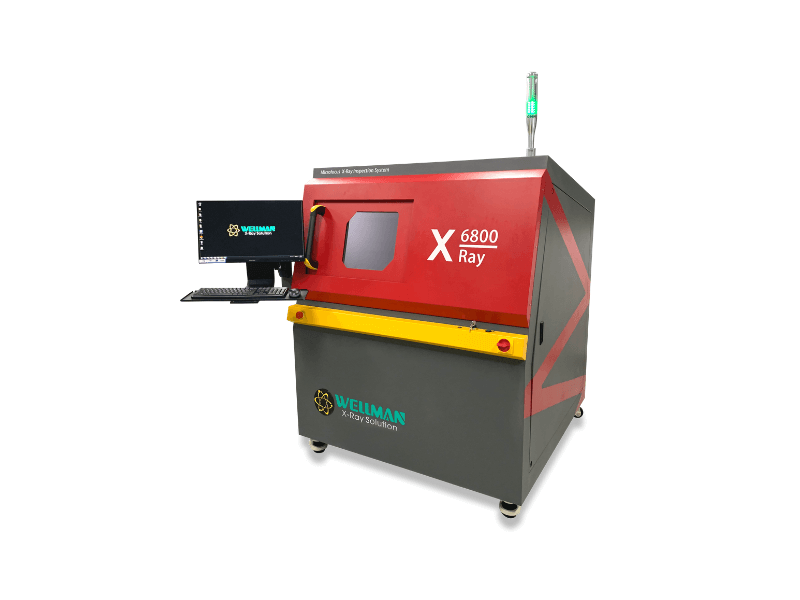

X6800 X-Ray Inspection System

The X6800 is a state-of-the-art x-ray inspection system that provides customers with advanced non-destructive testing capabilities. With its exceptional high-resolution imaging capabilities, this system is specifically designed to overcome the challenges associated with inspecting and analyzing a wide range of materials and products.

X8800 X-Ray Inspection system

The X8800 is one of our most innovative x-ray inspection systems that offers exceptional 2.5D x-ray imaging capabilities. This system is equipped with a powerful 130KV x-ray tube, enabling it to provide high-resolution imaging that can detect and analyze the intricacies of various materials and parts.

IL-3000 X-Ray Inspection System

The IL-3000 is a highly advanced in-line x-ray inspection system that is designed for use in quality control and non-destructive analysis of various materials and products. The system can be easily integrated into a production line, and it can be used to inspect various parts and materials at high speeds. This makes it ideal for businesses and manufacturers that require a quick, reliable and efficient quality control system.

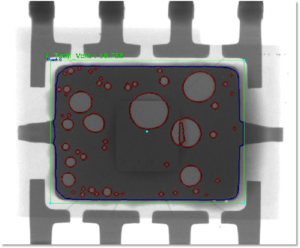

After PCB mounting, during the reflow soldering process, due to factors such as the temperature profile, the solder paste quality, there may be easy to have voids that directly affect product quality and stability, and X-Ray inspection can help improve the adjustment welding process.

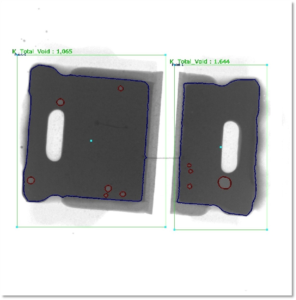

Voids generated by LED light soldering directly affect product quality and stability, and X-Ray inspection can inspect void rate to improve soldering process.

During the BGA welding process, due to factors such as the amount of tin, the temperature profile, and the quality of the solder paste, there may be problems such as bridging, voids, excess solder and open.

Check if there is loose core, bent pin, high or low pin, tilt element, bad waist, etc.