ISO Certified | Compliant With Local Radiation Safety Policy

Powerful and Safe-to-use X-Ray Inspection System

- ISO 9001

- CE / ROHS

- X-Ray Radiation Level ≤1μSv/h

SMD Tower /Box

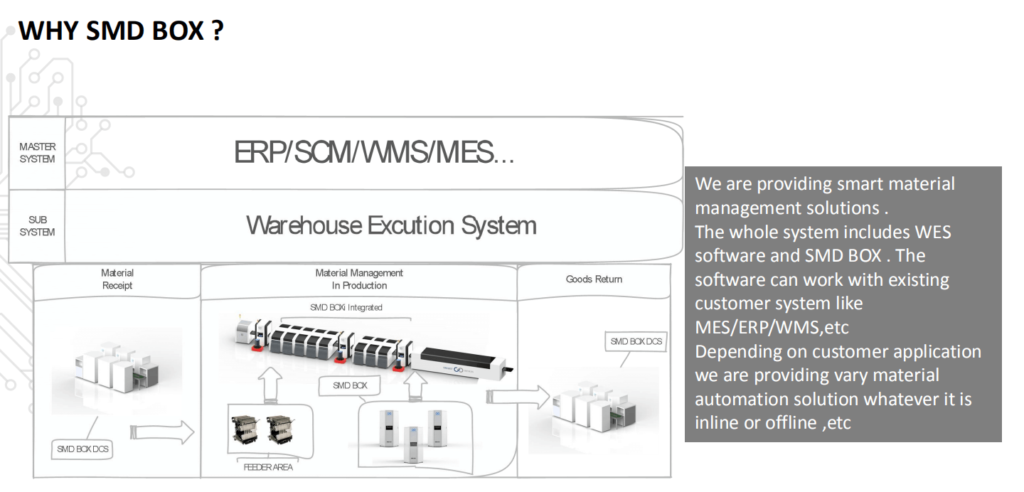

SMD Tower is a cutting-edge material management solution designed for electronics manufacturing. With its innovative inline storage system, it eliminates the need for manual movement or AGV, saving time and increasing efficiency. The cloud management capabilities enable real-time inventory management, while the modular design allows for easy adjustment of material amount according to production capacity. By integrating with SMD equipment, SMD Tower streamlines the production process, making it a must-have for any electronics manufacturer.

Features

- Ultra-high space utilization, standard capacity can reach about 840 reels

- Batch automatic scanning code & loading, compatible with barcode/QR code, one reel can be processed in 10 seconds

- Fully automatic in and out of storage, support 7” to 13” reels

- Support MES, ERP, WMS, and other management systems connection

- Manage and monitor SMD inventory to ensure inventory accuracy and avoid production interruption

- Provide a controlled environment for SMD componnents, monitor the life of the reel

- Back up and store all data automatically, supports quick search by scanning code, ensure the traceability of SMD components

- Can be customized according to customer requirements, and provide software technical support

- Can be heightened to 2.6 meters and expanded capacity to about 1280reels

Hardware Parameters

In and out of storage | Code scanning | Barcode and QR code |

Material type | SMD reel | |

Batch loading | Yes | |

Reel | Standard capacity | 840pcs (7″&10mm reel) |

Capacity after expansion | 1280pcs (7″&10mm reel) | |

Single reel cycle time | 10-12s | |

Mini height | 5mm | |

Max height | 25mm (customizable) | |

Max weight | 5KG (customizable) | |

System | Multi-tower connection | Support |

WMS management | Yes | |

Temperature and humidity warning | Support | |

Operation system | Windows 10 | |

Chip mounter communication | Optional | |

Management systems connection | MES, ERP, WMS etc. | |

Equipment | Dimensions | 1450mm (L) * 1900mm (W) * 1950mm (H) |

Height after expansion | 2600mm | |

Weight | 1500KG | |

Power supply | 220VAC, 16A | |

Power | 3000W | |

Industrial PC | I5 CPU, 8G RAM, 240GB SSD | |

Displayer | 17” touch screen | |

Working temperature | 0 – 40°C | |

Working humidity | 10 – 85% | |

Noise | 50dB | |

Air pressure | 0.5-0.7mpa | |

N2 interface | Support |

Software Parameters

Warehouse Management System | Material management | Transform the unique code for new incoming material, add to the total material table |

Tower setup | Set up new SMD tower and its locations | |

Supplier info | Supplier info management, add, delete or search | |

Customer Info | Customer info management, add, delete or search | |

Inventory management | Intelligent management of overall inventory | |

Inventory freeze | Freeze specific locations | |

Inventory verification | Take stock and update the data of stored reels | |

Scan the code and load | Scan the reel code and put into location | |

SMD Tower database | Location parameter table | Record the coordinate and size info of each location |

Current SMD tower table | Record the status of each location of the current SMD tower | |

In & out record | Record all records of material bin and material tray for traceability | |

Operation record | Record initialization, power on and off, alarm and other operations | |

Material bin function | Initialization | Initialize when the machine power on |

Single reel in | Put the reel on the designated position, load it in the tower after scanning code | |

Single reel out | Search for the specified reel, send it out | |

Batch loading | Load the reels into the tower in batches automatically | |

Place production orders | According to the production demand, upload the P/N or unique ID to the system for analysis, then lock the reels, and inform each SMD tower to unload | |

Unload to order | After receiving the production order of the system, unload the reels in batches | |

Lock expired reels | Lock the expired reels, prevent them from entering the production process |

Application