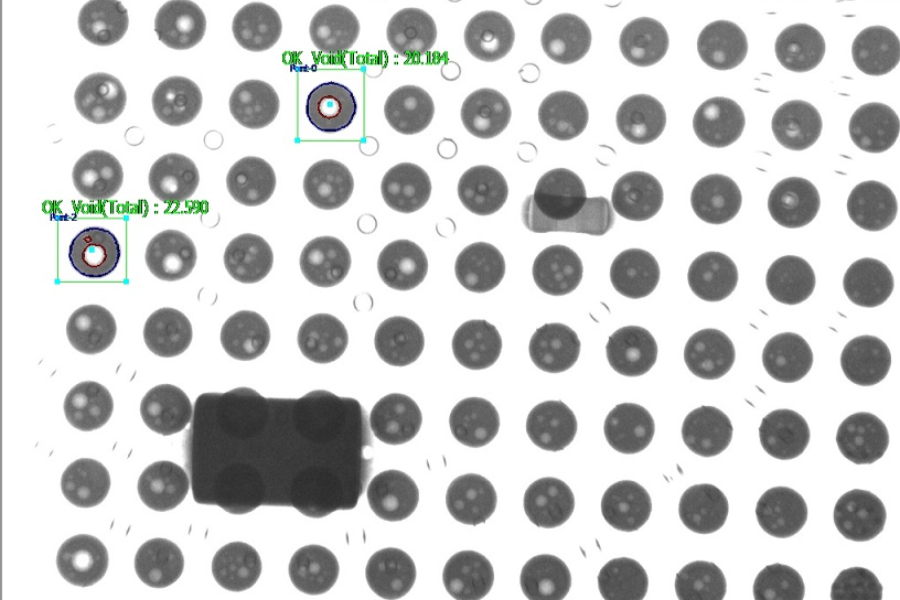

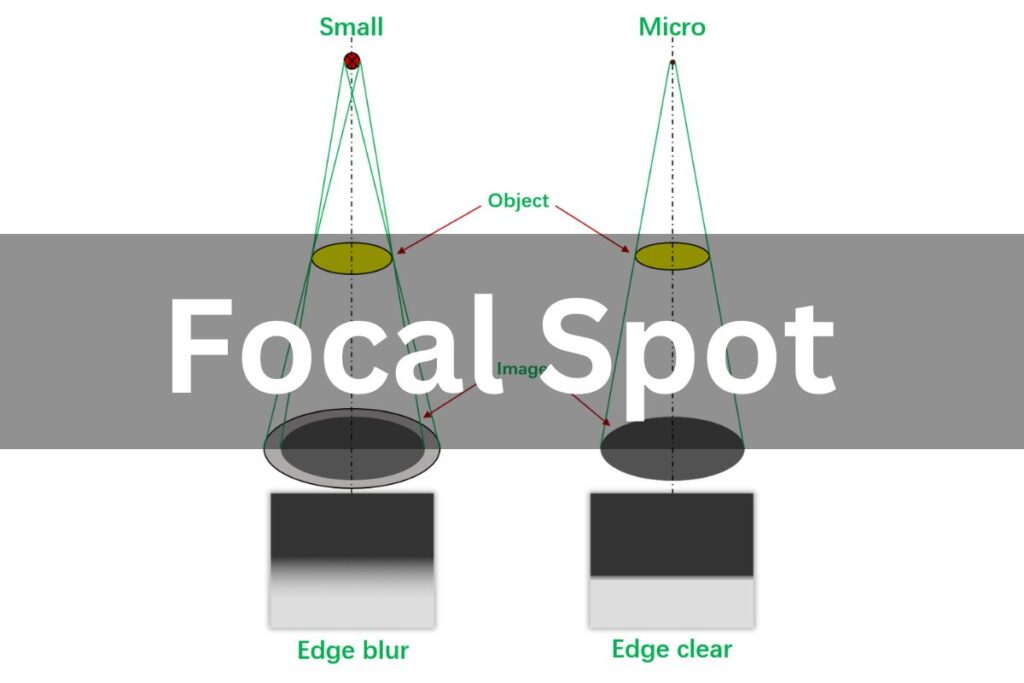

What are the main defects that industrial X-ray machine can find on the BGA of PCB?

Introduction In today’s fast-paced world, printed circuit boards (PCBs) are the backbone of numerous electronic devices, from smartphones to complex industrial machinery. These intricate boards house a vast array of components, including the ball grid array (BGA), which plays a crucial role in ensuring seamless functionality. However, even the slightest defect in the BGA can […]

What are the main defects that industrial X-ray machine can find on the BGA of PCB? Read More »