X-ray inspection Solution

Nondestructive X-Ray Inspection Systems and Solutions

- High resolution imaging

- High accurate and efficiency

- Non-destructive testing

- Customizable

Industrial X-Ray Inspection System Manufacturer

Wellman design and manufacturer x-ray inspection systems for a wide range of industrial applications. With years of experience in the x-ray inspection industry, Wellman has developed a reputation for providing high-quality, reliable systems that help ensure the safety and quality of products in industries such as electronics, batteries, semiconductors, and more.

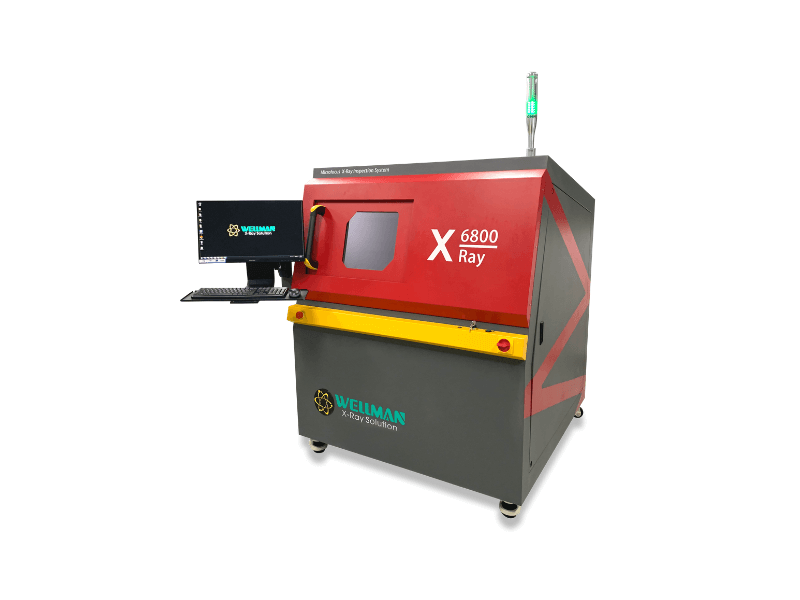

X-Ray Inspection Equipment

X-ray inspection systems are used to inspect printed circuit boards (PCBs), connectors, and other electronic components for defects such as broken solder joints, cracks, or voids.

X-Ray Parts Counter

X-Ray counter is a specialized type of SMD parts counter that uses x-ray technology to accurately count and inventory SMD components that are used in SMT assembly. The application of an X-ray counter is similar to that of a traditional SMD parts counter, but with the added benefit of being able to identify and count even the smallest and most intricate SMD components with high accuracy and high speed.

SMD Storage and Management System

SMD storage systems are designed to store and organize SMD components, typically in reels or trays. These systems help to reduce the risk of damage or contamination to the components, and also make it easier to access and manage inventory.

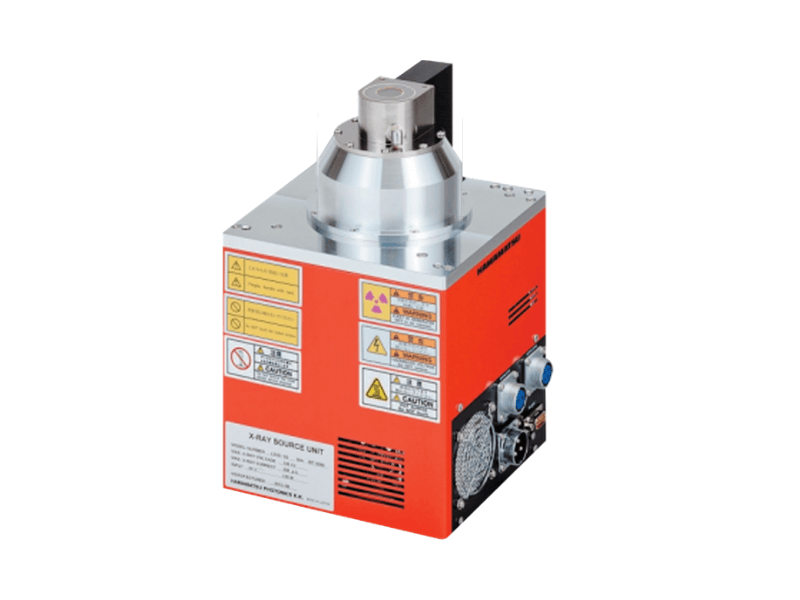

Sealed X-Ray Tube

Sealed X-ray tubes are an important part of an x-ray inspection system, as they provide a non-destructive way to inspect and image materials and parts. They are safe and reliable when used properly, but require appropriate safety measures to prevent harm to human tissue.

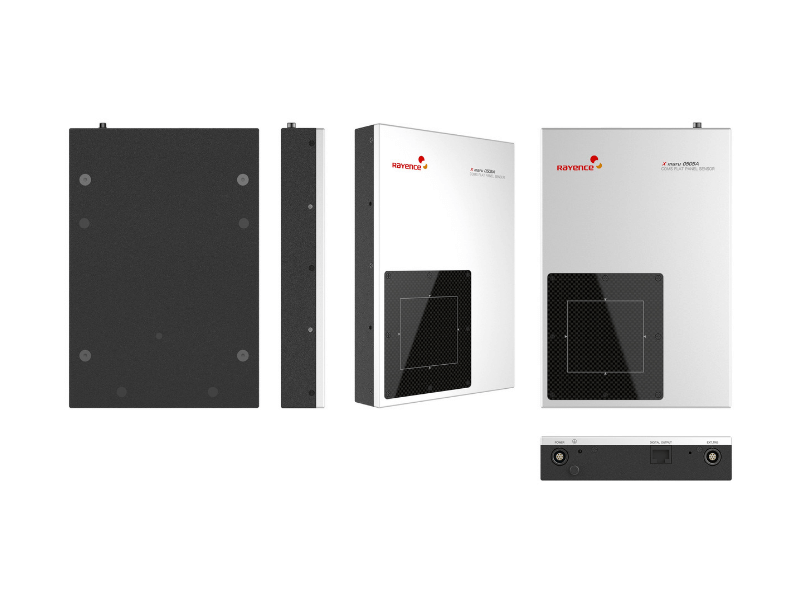

Flat Panel X-Ray Detector

Flat panel detector is a type of digital X-ray detector that uses a flat panel sensor to detect and convert X-rays into digital images. Unlike traditional film-based X-rays, panel detectors allow for real-time imaging, immediate review of the images, and the ability to store and manipulate the images electronically.

Served Industries

At Wellman, we specialize in providing cutting-edge x-ray inspection systems to a wide range of industries. Our advanced X-ray technology and experienced team allow us to deliver accurate, efficient, and cost-effective solutions for a variety of applications

Aerospace

Semicon

Batteries

Automotive

Consumer Products

Welding

Electric Power

Science & Research

Why Choose Wellman

Wellman is committed to developing and delivering innovative and reliable X-ray inspection solutions to customers worldwide. Our team of experts has the knowledge and experience to develop customized solutions that meet the specific needs of our customers, ensuring optimal performance and efficiency.

Quick Response

We understand the importance of timely support and quick response times. Our customer service team is available 24/7 to provide expert technical support, troubleshooting, and remote assistance.

Quality Guarantee

Quality is at the heart of everything we do at Wellman. We are committed to providing our customers with the most reliable, accurate, and efficient X-ray inspection solutions on the market.

Customer Service

We pride ourselves on our commitment to customer service. We work closely with our customers to understand their needs and develop customized solutions that meet their specific requirements.

Frequently Asked Questions

What is X-ray inspection?

X-ray inspection is a non-destructive method of detecting defects or foreign objects in products or packaging by passing X-rays through the item being inspected and analyzing the resulting image.

What products can be inspected using X-ray inspection systems?

X-ray inspection systems can be used to inspect a wide range of products, including food and beverage packaging, pharmaceuticals, electronics, and automotive parts.

How does X-ray inspection work?

X-ray inspection works by passing X-rays through the product or package being inspected. The X-rays are absorbed differently by different materials, allowing the system to detect defects, foreign objects, or other anomalies.

What are the benefits of X-ray inspection?

X-ray inspection can help ensure product quality and safety by detecting defects, foreign objects, or other issues that could affect product performance or consumer health. It can also help reduce waste and improve production efficiency by identifying and removing defective products from the production line.

Can X-ray inspection systems be customized to fit specific production lines?

Yes, X-ray inspection systems can be customized to fit the specific needs of different production lines, including the size and shape of products being inspected.

Are X-ray inspection systems expensive?

The cost of X-ray inspection systems can vary depending on the complexity of the system and the specific needs of the production line. However, the benefits of increased product quality and safety, reduced waste, and improved efficiency can make them a worthwhile investment for many companies.