Table of Contents

ToggleIntroduction

In the realm of industrial non-destructive testing (NDT) and quality control, flat panel detectors (FPDs) have become invaluable tools for detecting defects, flaws, and irregularities in various materials and products. These detectors capture images using X-rays, gamma rays, or other forms of radiation, and one crucial aspect of these images is the grayscale value, which plays a vital role in interpreting and understanding the information they convey.

What is Grayscale Value?

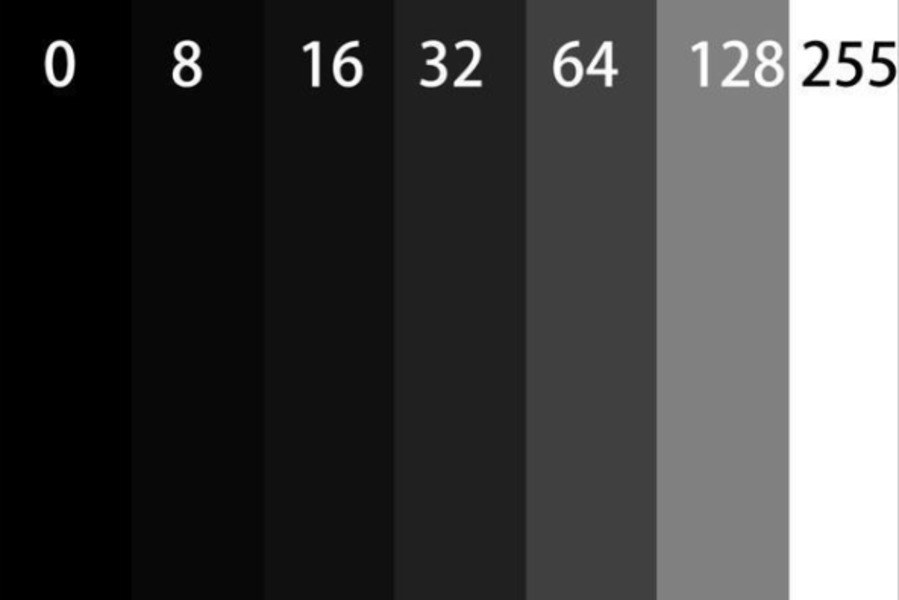

The grayscale value, also known as pixel intensity, refers to the brightness or darkness level of individual pixels in a digital image. In industrial imaging, grayscale values typically range from 0 to 255 or 0 to 65535, depending on the bit depth of the image. A value of 0 represents pure black, while the maximum value (255 or 65535) represents pure white. The values in between represent varying shades of gray, with lower values indicating darker shades and higher values indicating lighter shades.

Grayscale Values in Industrial Flat Panel Detectors

In industrial flat panel detectors, grayscale values are essential for accurately representing the varying levels of radiation attenuation within the inspected material or component. When radiation passes through different materials or structures, it is attenuated (absorbed or scattered) to varying degrees, depending on the density and composition of the materials. The flat panel detector captures this information and assigns appropriate grayscale values to each pixel, creating a detailed image that depicts the internal structures, densities, and potential defects or flaws.

Factors Affecting Grayscale Values

Several factors can influence the grayscale values in industrial flat panel detector images. One of the primary factors is the energy and intensity of the radiation beam used for imaging. Higher energy radiation tends to penetrate deeper and produce higher grayscale values, while lower energy radiation is more readily attenuated, resulting in lower grayscale values.

Additionally, the density and composition of the inspected material or component play a significant role. Dense materials or structures, such as metals or high-density inclusions, will attenuate radiation more strongly, resulting in lower grayscale values (darker shades), while less dense materials or voids will exhibit higher grayscale values (lighter shades).

The sensitivity and calibration of the flat panel detector itself can also impact the grayscale values. Proper calibration ensures accurate representation of radiation attenuation levels, while variations in detector sensitivity can lead to inconsistencies in grayscale values.

Interpreting Grayscale Values in Industrial Applications

Inspectors and technicians are trained to interpret grayscale values in industrial flat panel detector images. By analyzing the patterns and relative intensities of grayscale values, they can identify defects, flaws, or irregularities in the inspected materials or components.

For example, in the inspection of a welded joint, the grayscale values can reveal potential defects such as porosity, inclusions, or lack of fusion. Any deviations from the expected grayscale patterns may indicate the presence of these defects, enabling timely corrective actions and ensuring product quality.

Applications of Grayscale Values in Industry

Grayscale values are essential in various industrial sectors, including aerospace, automotive, construction, and manufacturing. They play a crucial role in quality control, defect detection, and ensuring product integrity.

In the aerospace industry, grayscale values are used to inspect critical components, such as aircraft engines, fuselages, and wings, for potential defects or fatigue cracks. In the automotive sector, grayscale values aid in the inspection of castings, welds, and other components to ensure they meet stringent quality standards.

Challenges and Limitations

While grayscale values provide valuable information, interpreting them in industrial applications can sometimes be challenging. Factors such as noise, artifacts, and complex material compositions can make it difficult to distinguish between different material densities or accurately assess grayscale values.

To overcome these challenges, advanced image processing techniques, such as contrast enhancement, noise reduction, and image segmentation, are often employed. Additionally, proper calibration and quality control measures are essential to ensure consistent and accurate grayscale value representation across different imaging systems and procedures.

Conclusion

In the industrial setting, the grayscale value of flat panel detectors is a crucial aspect that enables accurate representation and interpretation of radiation attenuation levels. By assigning appropriate grayscale values to each pixel, flat panel detectors create detailed images that reveal the internal structures, densities, and potential defects or flaws in inspected materials or components. Understanding grayscale values is essential for inspectors and technicians, as it allows them to identify defects, ensure product quality, and maintain safety standards. While challenges exist in grayscale value interpretation, advancements in imaging techniques and image processing continue to enhance the inspection capabilities of flat panel detectors, ultimately improving product quality and reliability across various industrial sectors.

FAQs

What is the typical range of grayscale values in industrial imaging?

The typical range of grayscale values in industrial imaging is either 0 to 255 (for 8-bit images) or 0 to 65535 (for 16-bit images). A value of 0 represents pure black, while the maximum value represents pure white, with varying shades of gray in between.How do grayscale values help in detecting defects in industrial components?

Grayscale values help detect defects by revealing deviations from the expected grayscale patterns. For example, in the inspection of a welded joint, a lack of fusion may appear as a darker area with lower grayscale values compared to the surrounding weld material, indicating a potential defect.Can grayscale values be affected by radiation energy and intensity?

Yes, grayscale values can be affected by the energy and intensity of the radiation beam used for imaging. Higher energy radiation tends to penetrate deeper and produce higher grayscale values, while lower energy radiation is more readily attenuated, resulting in lower grayscale values.Are grayscale values used in other industrial imaging techniques besides flat panel detectors?

Yes, grayscale values are essential in various industrial imaging techniques, including computed tomography (CT), digital radiography, and ultrasonic testing. In these techniques, grayscale values represent different material properties and characteristics, enabling accurate defect detection and quality control.Can advanced image processing techniques improve the interpretation of grayscale values in industrial applications?

Yes, advanced image processing techniques, such as contrast enhancement, noise reduction, and image segmentation, can improve the interpretation of grayscale values in industrial applications. These techniques can enhance the contrast between different material densities, reduce noise and artifacts, and segment regions of interest, making it easier to analyze and interpret grayscale values accurately.