Table of Contents

ToggleIntroduction

X-ray technology has revolutionized various fields, from medicine to industrial inspection. At the heart of this technology lies the X-ray tube, and one of the most advanced versions is the closed microfocus X-ray tube. But how exactly does this sophisticated device generate X-rays? Let’s delve into the fascinating world of microfocus X-ray tubes and uncover their secrets.

What is a Microfocus X-ray Tube?

A microfocus X-ray tube is a specialized type of X-ray tube that produces highly focused X-ray beams. Unlike conventional X-ray tubes, which generate a broader beam, microfocus tubes produce a very small focal spot, allowing for greater detail and precision. These tubes are pivotal in applications where detailed imaging is crucial, such as in medical diagnostics, electronic inspection, and scientific research.

Basic Principles of X-ray Generation

To understand how a microfocus X-ray tube works, it’s essential to grasp the basics of X-ray generation. X-rays are a form of electromagnetic radiation, similar to visible light but with much higher energy. They are produced when high-energy electrons collide with a metal target.

X-ray Spectrum

The X-ray spectrum consists of two main components: Bremsstrahlung radiation and characteristic radiation. Bremsstrahlung, or “braking radiation,” occurs when electrons are decelerated upon hitting the metal target, emitting a broad range of X-ray energies. Characteristic radiation, on the other hand, arises from electron transitions within the atoms of the target material, producing X-rays of specific energies unique to the target material.

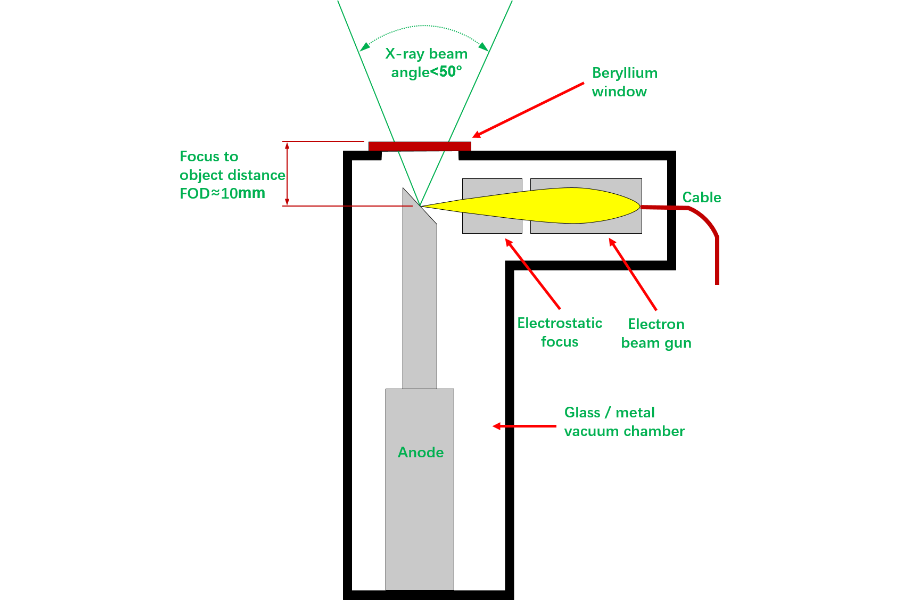

Components of a Closed Microfocus X-ray Tube

A closed microfocus X-ray tube comprises several critical components working in harmony:

Cathode

The cathode is the electron source in the X-ray tube. It typically consists of a filament that, when heated, emits electrons through thermionic emission. These electrons are then accelerated towards the anode.

Anode

The anode is the target where X-rays are produced. Made of high atomic number materials like tungsten, it converts the kinetic energy of the electrons into X-rays when they strike its surface.

Vacuum Chamber

The entire assembly is housed within a vacuum chamber. Maintaining a vacuum is crucial as it prevents the electrons from colliding with air molecules, which would reduce their energy and efficiency.

Control Mechanisms

Various control mechanisms regulate the flow of electrons, focusing the beam, and ensuring stable operation of the tube.

The Role of the Cathode

The cathode’s primary role is to emit electrons. This is achieved by heating the filament, which causes electrons to “boil off” and form an electron cloud. The type of cathode used can affect the tube’s performance. Common types include tungsten filaments and lanthanum hexaboride (LaB6) cathodes, each offering different advantages in terms of electron emission and lifespan.

The Function of the Anode

When electrons from the cathode strike the anode, their kinetic energy is converted into X-rays and heat. The choice of anode material is vital as it affects the efficiency and quality of the X-rays produced. Tungsten is often used due to its high atomic number and melting point, making it an ideal material for generating X-rays efficiently and withstanding the intense heat produced during operation.

Importance of the Vacuum Environment

A vacuum environment is essential for the efficient functioning of a microfocus X-ray tube. Without a vacuum, electrons would collide with air molecules, losing energy and scattering, which would decrease the efficiency and focus of the X-ray beam. The vacuum also protects the tube components from oxidation and contamination, extending the tube’s lifespan.

Focus and Intensity of the X-rays

Microfocus technology allows the X-ray tube to produce a highly focused beam with a very small focal spot. This increases the resolution and clarity of the images produced. The beam quality is influenced by the design of the tube, the materials used, and the precision of the control mechanisms.

Heat Management in X-ray Tubes

Generating X-rays produces a significant amount of heat, especially at the anode. Effective heat management is crucial to prevent damage and maintain consistent performance. Cooling systems, such as water or oil cooling, are typically used to dissipate heat. Some advanced tubes also use rotating anodes to spread the heat over a larger area, enhancing thermal stability.

Advantages of Closed Microfocus X-ray Tubes

Closed microfocus X-ray tubes offer several advantages over their conventional counterparts:

Precision

The ability to produce a highly focused beam allows for detailed imaging, essential in fields like medical diagnostics and materials science.

Efficiency

These tubes convert electron energy into X-rays more efficiently, resulting in better image quality with lower exposure times.

Safety

The closed design minimizes the risk of exposure to harmful X-rays, enhancing safety for both operators and patients.

Applications of Closed Microfocus X-ray Tubes

Medical Imaging

Microfocus X-ray tubes are invaluable in medical imaging, providing high-resolution images for accurate diagnosis and treatment planning.

Industrial Inspection

In industries such as electronics and aerospace, these tubes are used for inspecting tiny components and detecting flaws that would be invisible with standard X-ray equipment.

Scientific Research

Researchers rely on microfocus X-ray tubes to study materials at the microscopic level, enabling advancements in various scientific fields.

Maintenance and Longevity

Regular maintenance is crucial to ensure the longevity and optimal performance of microfocus X-ray tubes. Common issues include filament burnout and anode wear, which require periodic checks and replacements. Proper cooling and maintaining the vacuum environment are also essential for the tube’s durability.

Future Trends in X-ray Technology

The future of X-ray technology looks promising, with ongoing innovations aimed at improving efficiency, resolution, and safety. Potential developments include the integration of artificial intelligence for enhanced image analysis, miniaturization of components for portable X-ray devices, and the use of new materials to increase the durability and performance of X-ray tubes.

Conclusion

In conclusion, closed microfocus X-ray tubes are remarkable devices that generate X-rays through a well-coordinated process involving electron emission, acceleration, and collision with a target material. Their precision, efficiency, and safety make them indispensable in various fields, from medical imaging to industrial inspection and scientific research. As technology advances, we can expect even greater innovations in X-ray generation, further expanding their applications and capabilities.

FAQs

1. What makes microfocus X-ray tubes different from conventional X-ray tubes?

Microfocus X-ray tubes produce a much smaller focal spot, resulting in higher resolution and more detailed images compared to conventional X-ray tubes.

2. How are X-rays generated in a microfocus X-ray tube?

X-rays are generated when high-energy electrons emitted by the cathode strike the anode material, converting their kinetic energy into X-rays and heat.

3. Why is a vacuum environment necessary in an X-ray tube?

A vacuum environment prevents electrons from colliding with air molecules, which would reduce their energy and efficiency, and protects tube components from oxidation and contamination.

4. What materials are commonly used for the anode in microfocus X-ray tubes?

Tungsten is a common material used for the anode due to its high atomic number and melting point, making it efficient for X-ray production and capable of withstanding intense heat.

5. What are some future trends in X-ray technology?

Future trends include the integration of artificial intelligence for better image analysis, miniaturization for portable devices, and the use of new materials to enhance tube durability and performance.