Table of Contents

ToggleWhat is X-Ray

X-rays are a form of high-energy electromagnetic radiation with wavelengths shorter than ultraviolet light but longer than gamma rays. When X-rays pass through matter, they can penetrate it and create images of the inside – think bones, organs, etc. This makes them super useful for medical imaging. X-ray was discovered by Wilhelm Conrad Roentgen in 1895 and has since become an invaluable tool in various fields, particularly in medicine.

Brief History and Development of X-Ray Technology

Wilhelm Conrad Roentgen’s discovery of X-rays marked a groundbreaking moment in scientific history. His experiments with cathode rays and their ability to penetrate objects led to the accidental discovery of X-rays. Roentgen’s subsequent research and documentation of X-rays laid the foundation for further advancements in this field.

Over the years, X-ray technology has significantly evolved. From the early use of photographic plates to the advent of digital X-ray imaging, technological advancements have improved image quality, reduced radiation exposure, and enhanced the overall efficiency of X-ray examinations.

How Are X-Rays Produced?

X-rays are produced by accelerating electrons to high speeds and suddenly stopping them. This process takes place in a machine called an X-ray tube. Inside the tube, electrons are boiled off a heated cathode filament and focused into a beam. This beam is then accelerated by a high voltage towards a metal target called the anode. When the electrons slam into the anode and suddenly decelerate, about 1% of their kinetic energy is converted into X-ray photons. The X-rays then shoot out of the tube.

Applications of X-Ray Radiation

X-ray radiation plays a crucial role in medicine, enabling the diagnosis of various medical conditions. It is widely used in medical imaging to visualize internal structures such as bones, organs, and tissues. X-rays aid in the detection of fractures, infections, tumors, and other abnormalities, facilitating appropriate medical interventions. X-rays have many practical uses thanks to their penetrating abilities, especially in the medical field. Let’s explore some of the main ones.

Medical Imaging

X-rays allow doctors to see inside your body without cutting it open – invaluable for finding and diagnosing issues! Some examples:

Chest X-Rays

Perhaps the most common use. A chest X-ray produces images of your heart, lungs, blood vessels, airways, and the bones of your chest and spine. It can reveal pneumonia, heart problems, emphysema, and more.

Mammograms

X-rays of the breast used to detect early signs of breast cancer. Recommended yearly for women over 40.

CT Scans

CT (computed tomography) scans combine multiple X-ray images taken from different angles to see cross-sectional “slices” inside your body. This produces a 3D image of organs, bones, soft tissues, and blood vessels. CT scans help diagnose causes of pain, bleeding, infections, etc.

Airport Security

X-ray machines scan your bags at airport security checkpoints, detecting weapons, explosives, and other prohibited items. The images produced let agents visually inspect your luggage’s contents. Pretty nifty!

Industrial Imaging

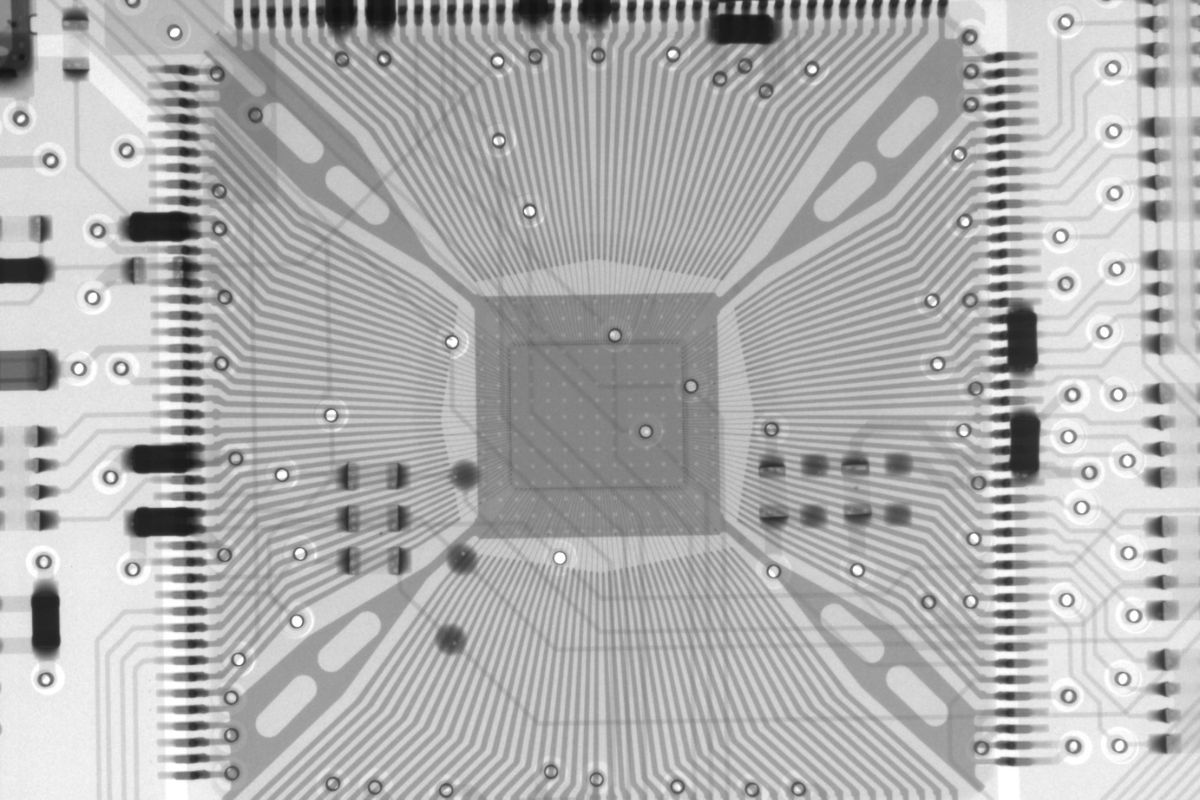

X-rays allow engineers to examine materials and products for defects without destroying them. For example, they can reveal cracks, voids, and leaks in machinery, pipelines, and welded joints.

Properties of X-Rays

The properties of X-rays are unique in several ways, which leads to their wide range of applications in fields such as medicine, astronomy, and materials science.

Here are some key properties of X-rays:

- High Energy and Short Wavelength: X-rays typically have energies in the range of 0.1 to 100 kilo-electronvolts (keV), which corresponds to wavelengths in the range of 10 to 0.01 nanometers. This is much shorter than the wavelength of visible light, which is why X-rays can interact with matter at the atomic level.

- Penetration: Due to their high energy, X-rays can penetrate many types of materials, including body tissue. This makes them useful for medical imaging. The degree of penetration depends on the material’s density and composition as well as the energy of the X-ray.

- Ionization: X-rays have enough energy to ionize atoms, meaning they can remove tightly bound electrons. This ionization can cause damage to biological tissue, which is why exposure to X-rays is carefully controlled in medical settings.

- Fluorescence: When X-rays interact with certain materials, they can cause the material to emit its own X-rays, a process known as fluorescence. This is used in X-ray fluorescence spectroscopy to analyze the elemental composition of materials.

- Diffraction: X-rays can be diffracted or scattered when they interact with a lattice of atoms in a crystal. This property is used in X-ray crystallography to determine the structure of complex molecules like proteins.

- Polarization: X-rays can be polarized, meaning their electric field oscillates in a specific direction. Polarization can provide information about the source of the X-rays and the materials they have interacted with.

- Travel at Speed of Light: Like all electromagnetic waves, X-rays travel at the speed of light in a vacuum (approximately 299,792 kilometers per second).

- Generation: X-rays can be generated in several ways, such as when high-energy electrons collide with a metal target, or when charged particles are accelerated. In nature, X-rays are produced in high-energy processes such as supernovae or around black holes.

It’s important to note that while X-rays have many beneficial applications, they also carry risks due to their ionizing nature. This means they have the potential to cause damage to living tissue, which is why safety protocols are in place for their use in medical and industrial settings.

Are X-Rays Dangerous?

X-ray radiation, like any ionizing radiation, carries potential risks. Prolonged or excessive exposure to X-rays can lead to biological damage, including cell mutations and an increased risk of cancer. With high or repeated doses, X-rays can mutate DNA and create free radicals that maim cell machinery. This damage can turn healthy cells cancerous. Radiosensitive tissues like breasts, thyroid glands, and gonads are especially vulnerable. However, it’s important to note that the risks associated with diagnostic X-rays are generally considered low compared to their significant benefits in medical diagnosis.

The Dose of Radiation and its Impact on Health

The radiation dose received during an X-ray examination depends on various factors, including the type of procedure, the area being imaged, and the equipment used. The amount of radiation is carefully controlled to ensure the lowest possible dose while obtaining the necessary diagnostic information. The impact of X-ray radiation on health varies depending on the individual’s age, overall health, and the cumulative dose received over time.

Factors That Affect the Level of Risk Posed by X-Ray Radiation

Several factors influence the level of risk posed by X-ray radiation. These include the frequency and duration of exposure, the age of the individual, and their specific sensitivity to radiation. Pregnant women and children, for example, are more susceptible to the potential risks of radiation.

Precautions and Safety Measures to Minimize Exposure

To ensure the safety of patients and healthcare professionals, various precautions and safety measures are implemented during X-ray procedures. These include the use of shielding, such as lead aprons and collars, to protect vital organs from unnecessary radiation exposure. Additionally, optimizing imaging protocols, adhering to radiation safety guidelines, and employing advanced imaging technologies help minimize radiation doses. Technicians also minimize the number of X-rays and only use the smallest dose needed to get a decent image.

Types of X-Ray Radiation

X-rays can be broadly categorized into diagnostic and therapeutic applications. Diagnostic X-rays are primarily used for medical imaging to aid in the diagnosis of diseases and conditions. Therapeutic X-rays, on the other hand, are employed in radiation therapy to treat certain types of cancers.

Brief Explanation of the Electromagnetic Spectrum

The electromagnetic spectrum encompasses a range of electromagnetic waves, including X-rays. X-rays fall between ultraviolet (UV) radiation and gamma rays in terms of wavelength and energy. Understanding the electromagnetic spectrum helps contextualize the properties and applications of X-rays.

Characteristics and Uses of Different Types of X-Ray Radiation

X-rays can be classified into different types based on their energy levels and penetration capabilities. Soft X-rays have lower energy and are suitable for imaging soft tissues, while hard X-rays have higher energy and are more effective for visualizing denser structures like bones. The appropriate type of X-ray radiation is selected based on the imaging requirements and the part of the body being examined.

X-Ray Radiation Levels in Different Places

In addition to medical and man-made sources, X-ray radiation is also present in the natural environment. Background radiation arises from cosmic rays, radioactive substances in the Earth’s crust, and even certain foods. However, the levels of natural background radiation are typically low and pose minimal health risks.

Comparison of Radiation Levels in Medical Facilities, Airports, and Industrial Settings

Radiation levels can vary in different settings. Medical facilities where X-rays are performed have measures in place to minimize radiation exposure for patients and staff. Airport security scanners also utilize X-rays, but the radiation doses are kept very low to ensure safety. Industrial settings may involve higher radiation levels, particularly in industries that handle radioactive materials or utilize X-ray inspection for quality control.

Regulatory Standards and Guidelines for Radiation Exposure

Regulatory bodies set standards and guidelines to ensure the safe use of X-ray radiation. These standards include permissible radiation dose limits for occupational exposure and public safety. Compliance with these regulations helps maintain a safe environment and minimize unnecessary radiation exposure.

What is X-Ray Inspection?

X-ray inspection, also known as X-ray imaging or radiographic inspection, is a non-destructive testing technique that uses X-rays to examine the internal structure of objects. It allows for the detection of defects, contaminants, or anomalies that may not be visible externally. X-ray inspection plays a crucial role in quality control, security screening, and various industries.

Applications of X-Ray Inspection in Various Fields

X-ray inspection finds applications across different industries and sectors. In the manufacturing industry, X-ray inspection is used to inspect welds, detect structural defects in materials, and ensure the integrity of components. In the healthcare industry, X-ray inspection assists in diagnosing and treating medical conditions. X-ray baggage scanners at airports enhance security by detecting prohibited items or potential threats.

Advantages and Limitations of X-Ray Inspection Technology

X-ray inspection technology offers several advantages, such as the ability to visualize internal structures without physical disassembly, rapid inspection times, and high detection sensitivity. However, it also has limitations, including difficulties in imaging certain materials and limitations in detecting certain types of defects or contaminants.

Are X-Ray Inspection Machines Safe?

X-ray inspection machines are generally safe when operated and maintained properly. X-ray inspection machines are designed with safety features to ensure the protection of operators and individuals being inspected. These features include shielding to contain radiation, interlocks to prevent accidental exposure, and monitoring systems to measure radiation levels. The level of radiation exposure from these machines is typically low and well below the recommended maximum dose limits set by regulatory bodies such as the US Food and Drug Administration (FDA) and the International Commission on Radiological Protection (ICRP).

Potential Health Risks Associated with X-Ray Inspection Machine

X-ray inspection machines are widely used in our world. However, it’s important to note that repeated exposure to ionizing radiation can increase the risk of cancer and other health problems. Therefore, it’s important to use X-ray inspection machines in accordance with established safety guidelines and to ensure that operators receive proper training and equipment is regularly maintained and calibrated.

Additionally, pregnant women and children are generally more sensitive to the effects of radiation and may require special precautions or alternative screening methods. It’s always a good idea to consult with a healthcare professional or radiation safety expert if you have any concerns about the safety of X-ray inspection machines.

How to Ensure the Safety of Individuals Operating X-Ray Machines

To ensure the safety of individuals operating X-ray inspection machines, training programs and safety protocols should be implemented. This includes proper education on radiation safety, guidelines for minimizing radiation exposure, and the use of personal protective equipment, and more:

- Proper Training: All individuals who operate X-ray machines should receive proper training on the safe use of the equipment. This training should cover topics such as radiation safety, equipment operation, and emergency procedures. Training should also be provided on a regular basis to ensure that operators stay up-to-date with the latest safety procedures and guidelines.

- Protective Equipment: Operators should wear appropriate protective equipment, such as lead aprons, thyroid collars, and leaded glasses, to minimize their exposure to ionizing radiation.

- Radiation Monitoring: Regular radiation monitoring should be conducted to ensure that operators are not being exposed to excessive levels of radiation. This monitoring could include personal dosimeters worn by individuals or area monitoring devices placed in the vicinity of the X-ray machine.

- Controlling Access: Access to X-ray machines should be restricted to authorized personnel only. This can be accomplished by implementing security measures such as access control systems, signage, and training programs.

- Equipment Maintenance: The X-ray machine should be properly maintained and inspected on a regular basis to ensure that it is functioning correctly and is safe to use.

- Emergency Procedures: Operators should be trained on emergency procedures in case of an accident involving the X-ray machine. This can include procedures for evacuating the area, contacting emergency services, and providing first aid to injured individuals.

By implementing these measures, the safety of individuals operating X-ray machines can be ensured, and the risks associated with ionizing radiation exposure can be minimized.

Where Can You Get X-Ray Inspection Service?

X-ray inspection services are available in various settings and locations. Medical facilities offer X-ray imaging services to aid in the diagnosis and treatment of medical conditions. Industrial companies utilize X-ray inspection for quality control and to ensure product integrity. Security checkpoints at airports utilize X-ray scanners to enhance passenger safety.

Popular Applications of X-Ray Inspection in Different Industries

Different industries benefit from X-ray inspection in their specific applications. For example, the automotive industry utilizes X-ray inspection to examine welds, engine components, and other critical parts. The aerospace industry employs X-ray inspection to ensure the integrity of aircraft structures. In the food industry, X-ray inspection is used to detect contaminants and foreign objects in packaged goods.

Advancements in X-Ray Inspection Technology and Its Impact on Various Sectors

Advancements in X-ray inspection technology continue to drive improvements in the accuracy, speed, and versatility of the inspection process. Digital imaging, enhanced resolution, and intelligent algorithms have revolutionized the capabilities of X-ray inspection machines. These advancements have had a significant impact on various sectors, enabling more precise inspection and quality control.

Conclusion

In conclusion, X-ray radiation is a powerful tool with diverse applications in medicine, industry, and security.

Understanding X-ray radiation and its safe utilization is essential for both medical professionals and individuals operating X-ray inspection machines. By following proper protocols and guidelines, we can harness the benefits of X-ray technology while minimizing potential risks. It is crucial to prioritize safety, ensure proper training, and stay informed about advancements in the field.

As technology continues to advance, we can expect further improvements in X-ray technology. The future holds promise for enhanced imaging techniques, increased efficiency, and even lower radiation doses. Continued research and development will pave the way for safer and more effective utilization of X-ray radiation.

Frequently Asked Questions (FAQs)

1. Are X-rays harmful to the body? X-rays carry potential risks, particularly with prolonged or excessive exposure. However, the doses used in diagnostic X-rays are generally considered safe, and the benefits of these procedures often outweigh the risks.

2. How does X-ray radiation affect pregnant women? Pregnant women are more sensitive to radiation, and precautions are taken to minimize their exposure to X-rays. However, when medically necessary, the benefits of an X-ray procedure can outweigh the potential risks, and appropriate shielding is used to protect the developing fetus.

3. Can X-ray inspection machines detect all types of defects? X-ray inspection machines have limitations in detecting certain types of defects, such as surface defects or defects within highly dense materials. However, they are highly effective in detecting internal structural defects, contaminants, and irregularities.

4. Are X-ray inspection machines safe for operators? X-ray inspection machines are designed with safety features and adhere to strict regulations to ensure operator safety. Proper training, adherence to safety protocols, and the use of personal protective equipment are essential to minimize potential risks.

5. How does X-ray technology continue to evolve? Advancements in X-ray technology focus on improving image quality, reducing radiation doses, and increasing the speed and accuracy of inspections. Digital imaging, intelligent algorithms, and enhanced resolution are some of the developments driving progress in the field.