Table of Contents

TogglePresentation

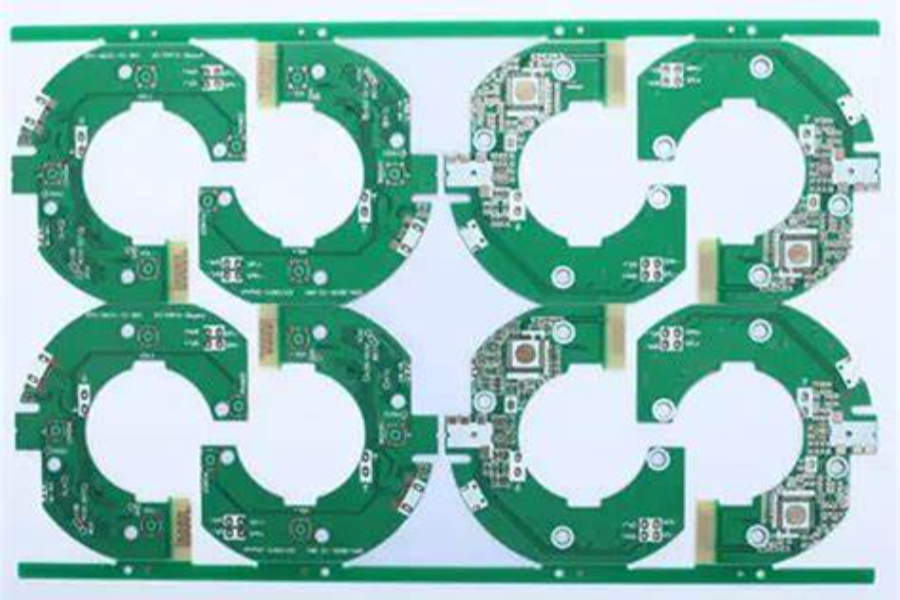

Definition of a PCB Mirrorboard

A PCB Mirrorboard, also known as a double-sided printed circuit board (PCB), is an essential component in the electronics industry. It is a specialized type of PCB that consists of conductive layers on both sides of an insulating substrate. These boards are designed to accommodate electronic components and interconnections on both sides, enabling a more compact and efficient layout compared to single-sided PCBs.

Importance in the electronics industry

PCB Mirrorboards play a crucial role in the electronics industry, as they are widely used in various applications, ranging from consumer electronics to industrial equipment. They offer several advantages over single-sided PCBs, including increased component density, improved signal routing, and better heat dissipation. As a result, PCB Mirrorboards have become an indispensable part of modern electronic devices, enabling the development of smaller, more powerful, and more efficient products.

Components of a PCB Mirrorboard

Substrate

The substrate is the foundation of a PCB Mirrorboard. It is typically made of an insulating material, such as fiberglass reinforced with epoxy resin (FR-4) or other specialized materials. The substrate acts as a mechanical support for the conductive layers and provides electrical insulation between them.

Conductive layers

The conductive layers are the most critical components of a PCB Mirrorboard. They consist of thin layers of copper or other conductive materials, such as aluminum or gold, deposited on both sides of the substrate. These layers are etched or patterned to create the desired circuit pathways and interconnections.

Vias and pads

Vias are small plated-through holes that allow electrical connections between the conductive layers on both sides of the PCB Mirrorboard. Pads are circular or rectangular areas on the conductive layers where electronic components are placed and soldered.

Manufacturing Process

Design and layout

The manufacturing process of a PCB Mirrorboard begins with the design and layout phase. Engineers use specialized computer-aided design (CAD) software to create the schematic diagrams and layout the components and interconnections on both sides of the board.

Etching and deposition

Once the design is finalized, the conductive layers are etched or deposited onto the substrate using various techniques, such as photolithography or direct metallization. This process creates the desired circuit patterns on both sides of the board.

Final assembly and testing

After the etching and deposition processes, the electronic components are placed and soldered onto the PCB Mirrorboard. The assembled board undergoes rigorous testing to ensure proper functionality and compliance with industry standards.

Applications of PCB Mirrorboards

Consumer electronics

PCB Mirrorboards are widely used in consumer electronics, such as smartphones, laptops, tablets, and gaming consoles. Their compact design and high component density allow for the integration of multiple functionalities into a single device.

Automotive industry

The automotive industry extensively utilizes PCB Mirrorboards in various electronic systems, including engine control units, infotainment systems, and advanced driver assistance systems (ADAS). Their reliability and ability to withstand harsh environments make them ideal for automotive applications.

Telecommunications

Telecommunications equipment, such as routers, switches, and base stations, rely heavily on PCB Mirrorboards. These boards enable the integration of complex circuitry and high-speed data transmission capabilities required for modern telecommunication systems.

Medical devices

PCB Mirrorboards are commonly used in medical devices, such as diagnostic equipment, patient monitoring systems, and implantable devices. Their compact size and reliability are essential in ensuring the proper functioning of these critical medical devices.

Advantages of PCB Mirrorboards

Compact design

One of the primary advantages of PCB Mirrorboards is their ability to accommodate a high density of components on both sides of the board. This compact design allows for the creation of smaller and more portable electronic devices.

Increased reliability

PCB Mirrorboards offer increased reliability compared to single-sided PCBs. The double-sided design provides better mechanical stability and improved heat dissipation, reducing the risk of component failure and extending the lifespan of the electronic device.

Cost-effectiveness

While the manufacturing process of PCB Mirrorboards is more complex than single-sided PCBs, their ability to accommodate more components in a smaller area can result in overall cost savings, particularly for high-volume production runs.

Flexibility in design

PCB Mirrorboards offer greater flexibility in design compared to single-sided PCBs. Engineers can optimize the layout and routing of components and interconnections, allowing for more efficient use of board space and better signal integrity.

Challenges and Limitations

Complex manufacturing process

The manufacturing process of PCB Mirrorboards is more complex than single-sided PCBs. It involves additional steps, such as etching or depositing conductive layers on both sides of the substrate and creating vias for interconnections. This complexity can lead to higher production costs and potential quality control issues.

Environmental concerns

The manufacturing of PCB Mirrorboards involves the use of various chemicals and materials that can have an impact on the environment. Proper disposal and recycling practices are essential to minimize the environmental footprint of these boards.

Design constraints

While PCB Mirrorboards offer flexibility in design, they also come with certain constraints. For example, the thickness of the substrate and the size of the vias can limit the number of conductive layers and the density of components that can be accommodated on the board.

Future Trends and Developments

Miniaturization

As the demand for smaller and more powerful electronic devices continues to grow, the trend towards miniaturization of PCB Mirrorboards will persist. Advances in manufacturing techniques and materials will enable the creation of even more compact and high-density boards.

Advanced materials

Researchers and manufacturers are continuously exploring new materials for PCB Mirrorboards, such as liquid crystal polymers (LCPs) and ceramics. These advanced materials offer improved thermal and electrical properties, enabling the development of high-performance electronic devices.

Flexible and wearable electronics

The development of flexible and wearable electronics is driving the need for PCB Mirrorboards that can bend and conform to various shapes. Flexible PCB Mirrorboards, made from flexible substrates like polyimide or liquid crystal polymers, are expected to play a crucial role in this emerging field.

Conclusion

PCB Mirrorboards are essential components in the electronics industry, enabling the development of compact, reliable, and high-performance electronic devices. With their double-sided design, these boards offer numerous advantages over single-sided PCBs, including increased component density, improved signal routing, and better heat dissipation. While the manufacturing process of PCB Mirrorboards is more complex and presents certain environmental challenges, ongoing research and advancements in materials and manufacturing techniques will continue to drive the evolution of these boards, enabling the creation of smaller, more efficient, and more capable electronic devices.

FAQs

1. What is the difference between a PCB Mirrorboard and a single-sided PCB?

A PCB Mirrorboard, also known as a double-sided PCB, has conductive layers on both sides of the insulating substrate, allowing for the placement of components and interconnections on both sides. In contrast, a single-sided PCB has a conductive layer on only one side of the substrate.

2. What materials are commonly used for the substrate in PCB Mirrorboards?

The most common substrate material used in PCB Mirrorboards is fiberglass reinforced with epoxy resin (FR-4). Other materials, such as polyimide, ceramics, and liquid crystal polymers (LCPs), are also used in specialized applications.

3. How are the conductive layers on a PCB Mirrorboard created?

The conductive layers on a PCB Mirrorboard are typically created through etching or deposition processes. Etching involves selectively removing unwanted copper from a copper-clad substrate, while deposition involves adding conductive materials directly onto the substrate.

4. What are the advantages of using PCB Mirrorboards over single-sided PCBs?

The main advantages of PCB Mirrorboards include increased component density, improved signal routing, better heat dissipation, enhanced reliability, and potential cost savings for high-volume production runs.

5. What challenges or limitations are associated with PCB Mirrorboards?

Some challenges and limitations of PCB Mirrorboards include a more complex manufacturing process, potential environmental concerns related to the use of chemicals and materials, and design constraints due to factors such as substrate thickness and via size.