Table of Contents

ToggleHow Industrial X-ray Technology Gives Manufacturers a Competitive Edge

In today’s electronics manufacturing environment, quality is no longer just a requirement—it is a competitive advantage. As products become smaller, more complex, and more reliability-critical, manufacturers face increasing pressure to detect defects earlier, reduce rework, and deliver consistent performance.

Industrial X-ray inspection has become one of the most powerful tools to meet these challenges. By revealing what traditional inspection methods cannot see, X-ray technology enables manufacturers to take full control of product quality—inside and out.

Seeing Beyond the Surface Changes Everything

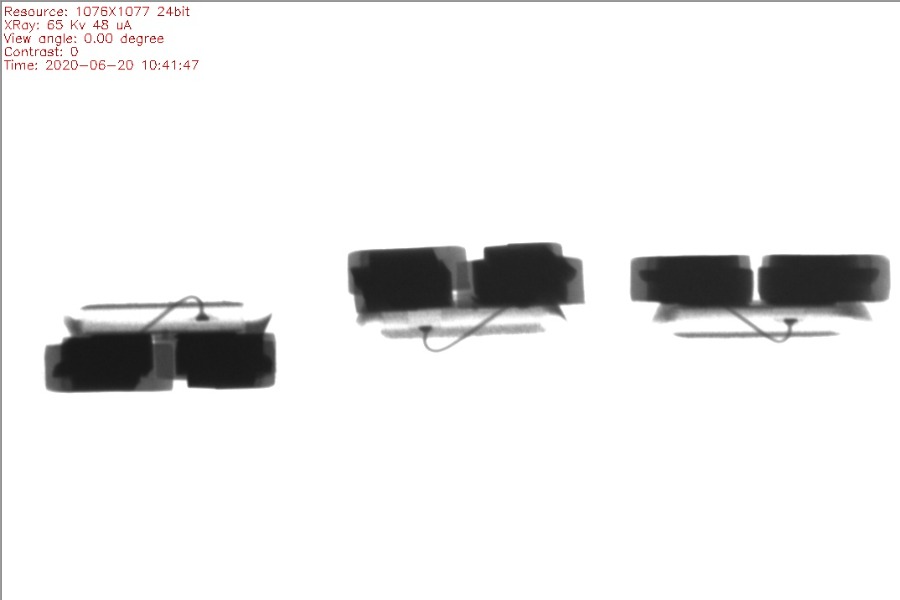

Many of the most critical defects in electronics manufacturing are hidden from view. Solder joints under BGAs, internal PCB layers, micro-cracks, and voids cannot be detected by visual inspection alone.

X-ray inspection makes the invisible visible.

By penetrating materials without damaging the product, X-ray systems provide clear insight into internal structures, allowing manufacturers to:

Detect hidden defects before they reach the next process

Reduce costly rework and scrap

Prevent field failures and customer complaints

Improve overall yield and process stability

For SMT, PCB, automotive electronics, and semiconductor manufacturing, this level of visibility is no longer optional—it is essential.

From Fast Screening to Deep Insight: 2D X-ray and 3D CT

Modern X-ray inspection solutions are designed to support different manufacturing needs:

2D X-ray inspection is ideal for production environments that require speed and efficiency. It enables quick identification of common issues such as solder voids, bridges, shorts, and misalignment, making it a reliable tool for daily quality control.

3D X-ray CT inspection goes a step further. By reconstructing a complete 3D model of the product, CT allows engineers to analyze internal structures layer by layer. This makes it especially valuable for:

Advanced PCB and high-density assemblies

Automotive and safety-critical electronics

Failure analysis and process optimization

R&D and new product introduction

Together, 2D and 3D inspection create a powerful, flexible quality strategy.

Reduce Risk, Increase Confidence

Internal defects are not just technical issues—they are business risks. A single undetected problem can lead to production delays, recalls, or long-term damage to brand reputation.

With industrial X-ray inspection, manufacturers gain:

Higher confidence in product reliability

Earlier detection of process issues

Better data for continuous improvement

Stronger compliance with industry standards

This is especially critical in industries such as automotive electronics, new energy, and medical devices, where reliability and traceability are non-negotiable.

Why Manufacturers Choose Wellman X-ray

At Wellman X-ray, we understand the real challenges faced on the production floor. Our X-ray inspection solutions are designed not only for image quality, but also for usability, efficiency, and long-term value.

Our systems help manufacturers:

Improve defect detection accuracy

Optimize inspection workflows

Support both production and engineering needs

Scale quality control as products evolve

Whether you need fast SMT inspection or advanced 3D CT analysis, Wellman X-ray delivers solutions that grow with your manufacturing goals.

Build Quality into Every Product

In a market where quality defines success, the ability to inspect what others cannot see makes all the difference. Industrial X-ray inspection is more than a quality tool—it is a strategic investment in reliability, efficiency, and customer trust.

Wellman X-ray is your partner in smarter inspection and better manufacturing.