Table of Contents

ToggleThe Beginning of Surface Mount Technology

The origins of surface mount technology (SMT) can be traced back to the 1960s when the demand for miniaturized electronic devices began to surge rapidly. Traditional through-hole technology, where components were mounted by inserting their leads into holes drilled in printed circuit boards (PCBs), had significant limitations in terms of size and density. These constraints hindered the development of smaller and more compact electronic devices, which were becoming increasingly desirable in various industries. As a result, researchers and engineers began exploring alternative methods of component mounting, ultimately paving the way for the development of SMT. This new approach allowed components to be mounted directly onto the surface of PCBs, enabling more compact designs and higher component densities, which addressed the growing demand for miniaturization.

The Rise of Integrated Circuits

The advent of integrated circuits (ICs) played a crucial role in the development of SMT. As ICs became more complex and powerful, with an ever-increasing number of transistors and other components integrated onto a single chip, the need for more efficient packaging and assembly methods became paramount. Traditional through-hole mounting techniques were simply not suitable for the high density required by these advanced ICs. The physical limitations of through-hole mounting, such as the size of the holes and the spacing between them, made it increasingly difficult to accommodate the growing complexity of ICs. This challenge drove the electronics industry to seek alternative solutions, and SMT emerged as a viable and promising approach to address these mounting and packaging needs.

The Emergence of Surface Mount Devices (SMDs)

To accommodate the new SMT approach, electronic component manufacturers developed specialized surface mount devices (SMDs) designed specifically for surface mounting. These components had terminals or leads that could be soldered directly onto the surface of PCBs, eliminating the need for through-hole mounting. SMDs came in various shapes and sizes, including chip capacitors, chip resistors, and small outline integrated circuits (SOICs), among others. The development of these specialized components was a critical step in enabling the widespread adoption of SMT, as it provided the necessary hardware to support this new mounting technique.

The Advantages of Surface Mount Technology

Surface mount technology offered several significant advantages over traditional through-hole mounting techniques, which drove its rapid adoption across the electronics industry:

1. Increased Component Density

SMT allowed for much higher component densities on PCBs compared to through-hole mounting. By eliminating the need for holes and the associated spacing requirements, SMT enabled more components to be placed within the same board area, resulting in more compact and efficient designs. This was particularly important for portable and handheld devices, where space was at a premium.

2. Reduced Board Size

With SMDs mounted directly on the surface, PCBs could be made significantly smaller than their through-hole counterparts. This reduction in board size not only contributed to the overall miniaturization of electronic devices but also reduced material costs and improved efficiency in manufacturing processes.

3. Improved Performance

SMT reduced the length of electrical connections between components, leading to improved signal integrity and faster signal propagation. Shorter interconnections minimized parasitic effects, such as capacitance and inductance, which could degrade signal quality and introduce noise or interference. This improved performance was particularly important in high-frequency and high-speed applications.

4. Automated Assembly

SMT facilitated automated assembly processes, increasing production efficiency and reducing labor costs. The surface mounting of components allowed for the development of specialized pick-and-place machines that could rapidly and accurately place SMDs onto PCBs, significantly improving throughput and reducing the potential for human error.

5. Reduced Weight and Profile

SMT components and assemblies tend to be lighter and have a lower profile compared to their through-hole counterparts. This weight reduction was particularly advantageous in applications such as aerospace and portable electronics, where every gram counts. The lower profile also enabled the design of sleeker and more compact devices.

The Transition to Surface Mount Technology

The transition from through-hole to surface mount technology was a gradual process that required significant changes in manufacturing processes, equipment, and materials across the electronics industry. PCB design and layout had to be adapted to accommodate the unique requirements of SMDs, including different pad shapes, sizes, and spacing. New soldering techniques, such as reflow soldering, were developed to effectively bond SMDs to the PCB surface, replacing the traditional wave soldering methods used for through-hole components.

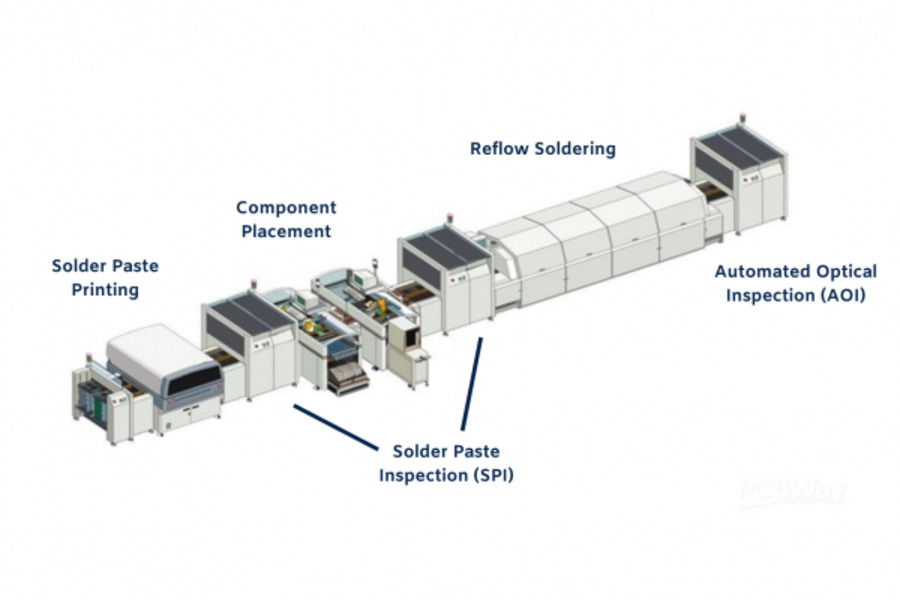

Manufacturing facilities had to invest in specialized equipment, such as pick-and-place machines, reflow ovens, and automated optical inspection systems, to support the SMT assembly process. Additionally, new materials and processes were introduced to ensure reliable and robust solder joints, such as solder paste and flux formulations specifically designed for SMT applications.

The Impact of Surface Mount Technology

Surface mount technology revolutionized the electronics industry, enabling the development of smaller, more powerful, and more reliable electronic devices across a wide range of applications. The ability to pack more components into a smaller space opened up new possibilities for product design and innovation.

In the consumer electronics sector, SMT played a pivotal role in the miniaturization of devices such as smartphones, laptops, and tablets, allowing for increasingly compact and portable form factors. The telecommunications industry benefited from SMT’s ability to enable high-density circuit boards, enabling the development of more advanced and feature-rich networking equipment and infrastructure.

The aerospace and defense industries also embraced SMT, taking advantage of the weight savings and improved reliability offered by surface mount assemblies. This was particularly important in applications where weight and space constraints were critical, such as in satellites and aircraft systems.

The Future of Surface Mount Technology

As the demand for miniaturization and high-density packaging continues to grow, surface mount technology is expected to evolve further to meet these requirements. Advancements in materials, component packaging, and assembly processes will likely drive the development of even smaller and more efficient electronic devices.

One area of ongoing research and development is the miniaturization of SMDs themselves. Researchers are exploring new materials and fabrication techniques to create ultra-small components, such as wafer-level chip scale packages (WLCSP) and ultra-thin chip capacitors, which can further increase component density and enable even more compact designs.

Another area of focus is the development of advanced assembly techniques, such as 3D packaging and System-in-Package (SiP) technologies. These approaches involve stacking or integrating multiple chips or components into a single package, enabling higher levels of integration and functionality within a smaller footprint.

Additionally, the ongoing evolution of materials and processes aims to improve the reliability and performance of SMT assemblies, addressing challenges such as thermal management, electromagnetic interference, and environmental robustness.

Challenges and Considerations

While surface mount technology offers numerous advantages, it also presents challenges that must be addressed to ensure reliable and high-quality products:

1. Thermal Management

The high density of components in SMT assemblies can lead to significant thermal management challenges. As more components are packed into a smaller space, the heat dissipation requirements increase, potentially leading to hotspots and thermal stress. Careful design and implementation of cooling solutions, such as heat sinks, fans, or advanced thermal interface materials, are necessary to ensure proper thermal management and prevent component failure or degradation.

2. Reliability Concerns

SMT components and assemblies can be more susceptible to environmental factors such as vibration, shock, and temperature extremes compared to their through-hole counterparts. The small size and surface mounting of components can make them more vulnerable to mechanical stress and fatigue, potentially leading to solder joint failures or component cracking. Robust design practices, careful material selection, and rigorous testing are essential to ensure the reliability of SMT assemblies in various operating environments.

3. Rework and Repair

Reworking or repairing SMT assemblies can be more challenging due to the small size of components and interconnections. Traditional through-hole rework techniques are often not suitable for SMDs, requiring specialized tools and processes. Skilled technicians and specialized equipment, such as hot air rework stations and microscopes, are necessary to ensure successful rework or repair operations without damaging adjacent components or the PCB itself.

4. Inspection and Testing

Inspecting and testing SMT assemblies requires specialized equipment and techniques to ensure quality and reliability. Traditional visual inspection methods may not be sufficient to detect defects or anomalies in the tiny solder joints or component interconnections. Advanced inspection techniques, such as automated optical inspection (AOI), X-ray inspection, and flying probe testing, are often employed to thoroughly evaluate SMT assemblies and identify potential issues.

5. Obsolescence Management

The rapid pace of technological advancements in the electronics industry can lead to component obsolescence, where certain SMDs or related materials become unavailable or discontinued by manufacturers. This can pose significant challenges for long-lifecycle products or systems that require ongoing maintenance and repair. Proactive obsolescence management practices, such as component lifecycle monitoring, last-time buys, and alternative component sourcing, are essential to mitigate the risks associated with component unavailability.

The Future of Electronics Manufacturing

As the electronics industry continues to evolve, driven by the ever-increasing demand for smaller, more powerful, and more efficient devices, surface mount technology will undoubtedly play a vital role in enabling.