Table of Contents

ToggleIntro

As vehicles become more intelligent and electric, automotive electronics play a critical role in ensuring safety, reliability, and performance. From engine control units (ECUs) to power modules and sensors, these assemblies must meet the highest quality standards.

However, many defects are hidden beneath components or encapsulated materials, making them invisible to traditional optical inspection.

This is where X-ray inspection becomes indispensable — providing non-destructive, high-resolution imaging to detect hidden defects that could compromise product reliability.

1. Solder Joint Voids

Solder joint voids are one of the most common and critical issues in automotive electronics. They occur when air pockets or gas are trapped during soldering, weakening the electrical and thermal connection.

X-ray detection capabilities:

• Quantifies void percentage within BGA, QFN, or power MOSFET joints

• Detects insufficient solder or incomplete wetting

• Enables process optimization to reduce void rates

Why it matters:

High void content can lead to thermal fatigue, poor heat dissipation, and eventual component failure — unacceptable in automotive-grade systems.

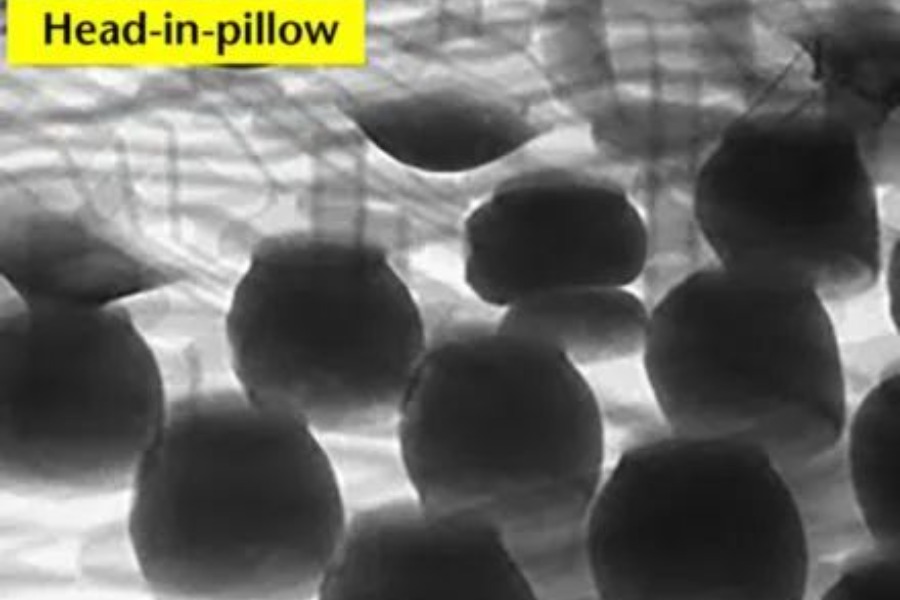

2. Head-in-Pillow (HiP) Defects

Head-in-Pillow defects occur when the solder ball and the paste fail to fully merge during reflow. This results in intermittent electrical contact that may pass initial tests but fail under vibration or thermal cycling.

X-ray advantages:

• Clearly reveals separation or poor wetting at the solder ball interface

• Detects defects invisible to AOI (Automated Optical Inspection)

• Ensures long-term reliability in mission-critical electronics

Typical applications:

Powertrain control modules, ADAS systems, and battery management units.

3. Solder Bridging and Short Circuits

Solder bridging occurs when excess solder creates unintended electrical connections between adjacent pads or leads.

X-ray inspection features:

• Detects hidden bridges under components such as BGAs or QFNs

• Provides precise location for rework or repair

• Prevents short circuits that could lead to catastrophic system failures

Why X-ray:

Optical inspection often cannot see beneath components — only X-ray reveals the internal structure and hidden connections.

4. Wire Bond Defects

In power modules and hybrid ICs, wire bonds connect semiconductor dies to lead frames or substrates. Breaks, lifts, or improper bonding can severely affect performance.

X-ray and CT imaging reveal:

• Wire bond integrity and loop geometry

• Broken or lifted bonds

• Internal cracks or corrosion beneath encapsulant

Impact:

Early detection of wire bond defects prevents current leakage, overheating, and device burnout — especially important for EV inverters and power modules.

5. Cracks and Voids in Die Attach Layers

In high-power devices, the die attach layer (solder or adhesive) must ensure efficient heat transfer. Any voids or cracks can cause thermal stress, leading to delamination or die failure.

3D CT capabilities:

• Visualizes the full volume of die attach layers

• Quantifies void ratio and distribution

• Detects micro-cracks not visible on 2D X-ray

Use case:

Ensures long-term thermal stability in IGBT modules, SiC MOSFETs, and power controllers.

Conclusion

Automotive electronics must operate reliably under extreme conditions — vibration, heat, and long duty cycles.

X-ray and CT inspection are essential tools for detecting hidden defects that could otherwise lead to costly recalls or safety issues.

Wellman X-ray provides advanced 2D and 3D CT inspection systems designed for automotive-grade quality assurance.