ISO Certified | Compliant With Local Radiation Safety Policy

Powerful and Safe-to-use X-Ray Inspection System

- ISO 9001

- CE / ROHS

- X-Ray Radiation Level ≤1μSv/h

X8800 X-Ray Inspection System

X8800 is one of our most advanced real-time x-ray inspection systems, it can be widely used in Non-destructive analysis of semiconductor, SMT, and electric component quality checking. By high resolution imaging, engineers can easily to find defects inside semiconductors , batteries , small metal casting, electronics cables and connectors, 3D Printing module, medical device and parts.

Features

- 40kv – 90kv closed type micro-focus closed x-ray tube(Hamamatsu), focal spot size down to 5µ

- HD digital flat panel detector

- 60° detector tilting for oblique angle viewing, x-ray image keep central while tilt.

- 400mm x400mm inspection area with 10kg load capacity

- Automatic navigation software provides easy positioning and identification of defects area.

- Adjustable 6 axis linkage system

- Quick inspection parameter settings, inspection area adjust.

- Inspection software provides access to create advanced inspection procedure for automated inspection in large quantities.

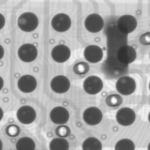

- Multifunctional measuring tools including BGA void detection and automatic calculations, radius, area, perimeter, measuring, repeat programming

- Industrial PC with Windows 7 PRO, 24” LCD flat panel display

- Low maintanance requirements

- 360° rotary sample table

- High resolution imaging

- User-friendly software interface

Specifiactions

| X-ray source | Brand | Japan Hamamatsu |

| Type | Closed, microfocus | |

| Max tube voltage | 130kV | |

| Max tube current | 300μA | |

| Focal spot size | 5μm | |

| Function | Auto preheat | |

| Flat panel detector | Brand | IRAY |

| Effective area | 130mm*130mm | |

| Pixel size | 85μm | |

| Resolution | 1536*1536 | |

| Frame rate | 20fps | |

| Tiltable angle | ±45° | |

| Table | Size | 400mm*400mm |

| Detectable area | 400mm*400mm | |

| Max load | 10kg | |

| Equipment | Magnification | Geometry 200X, System 1500X |

| Inspection speed | Max 3.0s/point | |

| Dimensions | 1550mm (L) * 1600mm (W) * 1700mm (H) | |

| Weight | 1800kg | |

| Power supply | AC110-220V 50/60HZ | |

| Max power | 1800W | |

| Industrial PC | I5 CPU, 4G RAM, 240GB SSD | |

| Displayer | 24″ HDMI LCD | |

| Safety | Radiation leakage | No leakage, international standard: ≤1μSv/h |

| Lead glass observation window | Transparent lead glass window shields radiation to observe the inner status. | |

| Window and back door safety interlock | Once users open the window or back door, X-ray tube will power off immediately. When the window or back door is open, users can’t turn on the X-ray. | |

| Electromagnetic safety switch | Lock once the X-ray is on, users can’t open the observation window. | |

| Emergency stop | Next to the operation position, press to power off. | |

| Tube protection | User can’t leave the software to if you don’t close the X-ray tube. |

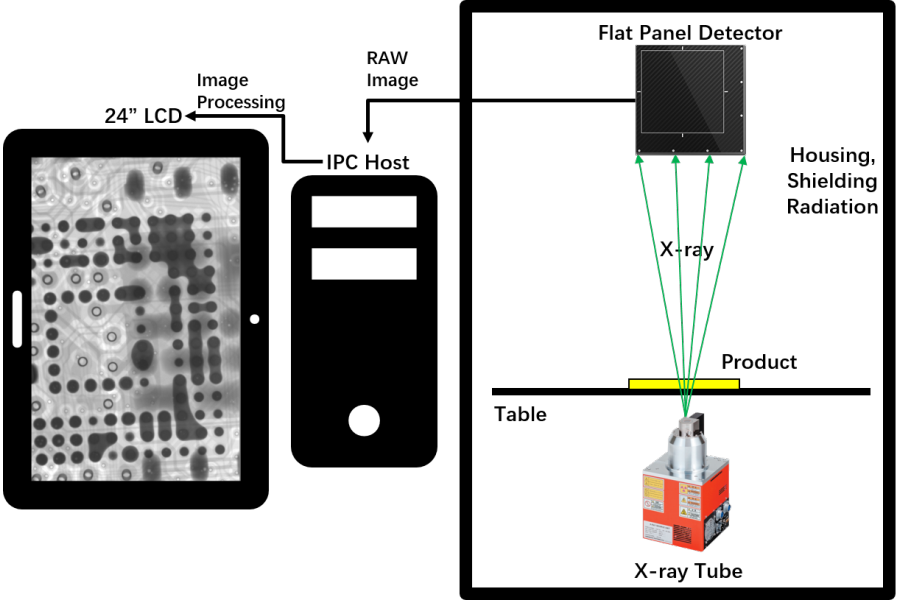

Working Principle

Application

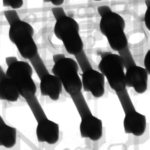

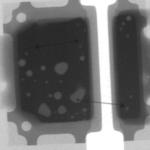

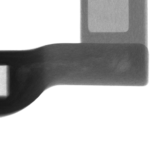

BGA , CSP , Flip Chip, LED , Fuse, Diode, Sensors, PCB Voids Inspection

Semiconductor , Battery Industry , Small Metal Casting, Electronics Cables and Connectors, 3D Printing Module, Medical Device and Parts.

Radiation Safety Guarantee

All X-ray machines manufactured by Wellman meet the requirement of FDA-CDRH Regulation CFR 21 1020.40 Subchapter J for cabinet x-ray systems. The FDA – CDRH standard for cabinet x-ray systems states that radiation emission shall not more than. 5millirem a /hr.2″from any external surface. Our machines (X-Ray Radiation Level <1μSv/h ) are typically 5-10 times less emission than the standards, so there are no radiation concerns for operators.

| Operation Safety | |

|---|---|

| Radiation Leakage | No leakage, international standard: ≤1μSv/h |

| Lead Glass Observation Window | Transparent lead glass window to shields radiation, safe to observe the inner status. |

| Window and Back Door Safety Interlock | Once open the window or back door, the X-ray tube will power off immediately. When the window or back door is open, the operator cannot turn on the X-ray. |

| Electromagnetic Safety Switch | Once the X-ray is on, the window will automatically lock, so the operator can’t open the window. |