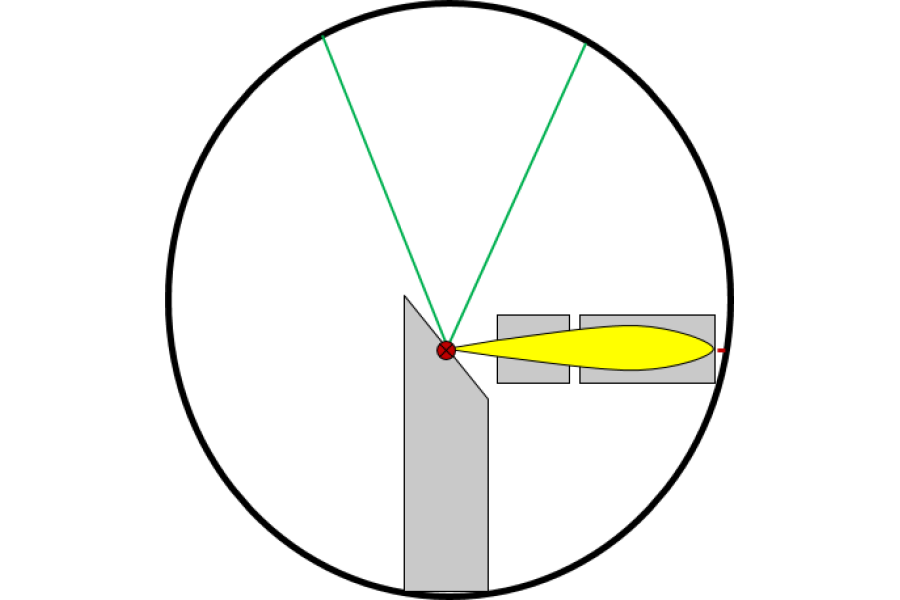

What is the Focal Spot Size?

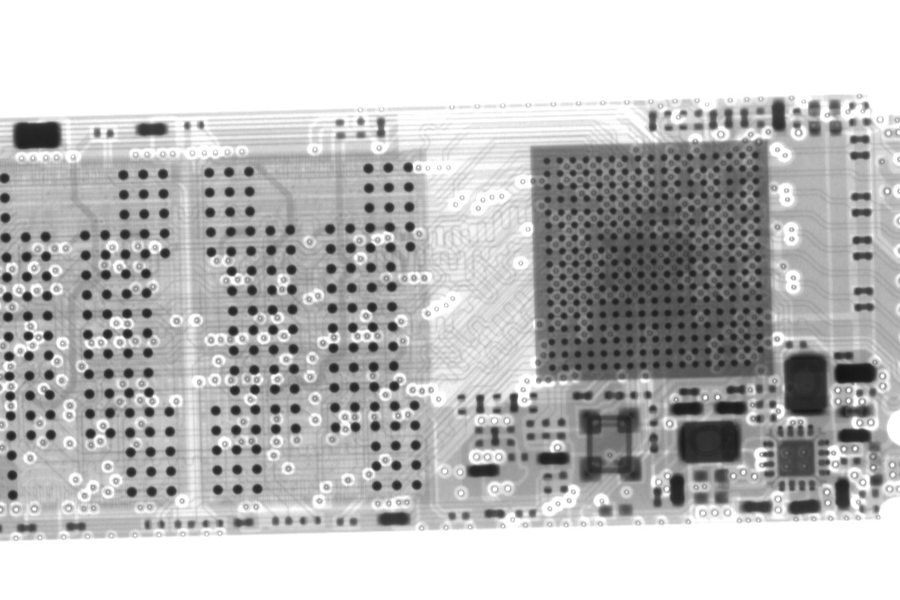

Definition of Focal Spot Size The focal spot size, also known as the effective focal spot size, is a crucial parameter in X-ray imaging systems. It refers to the area on the anode target of an X-ray tube from which the X-rays are generated. The focal spot size directly impacts the spatial resolution and image […]

What is the Focal Spot Size? Read More »