ISO Certified | Compliant With Local Radiation Safety Policy

Radiation Safety Permits

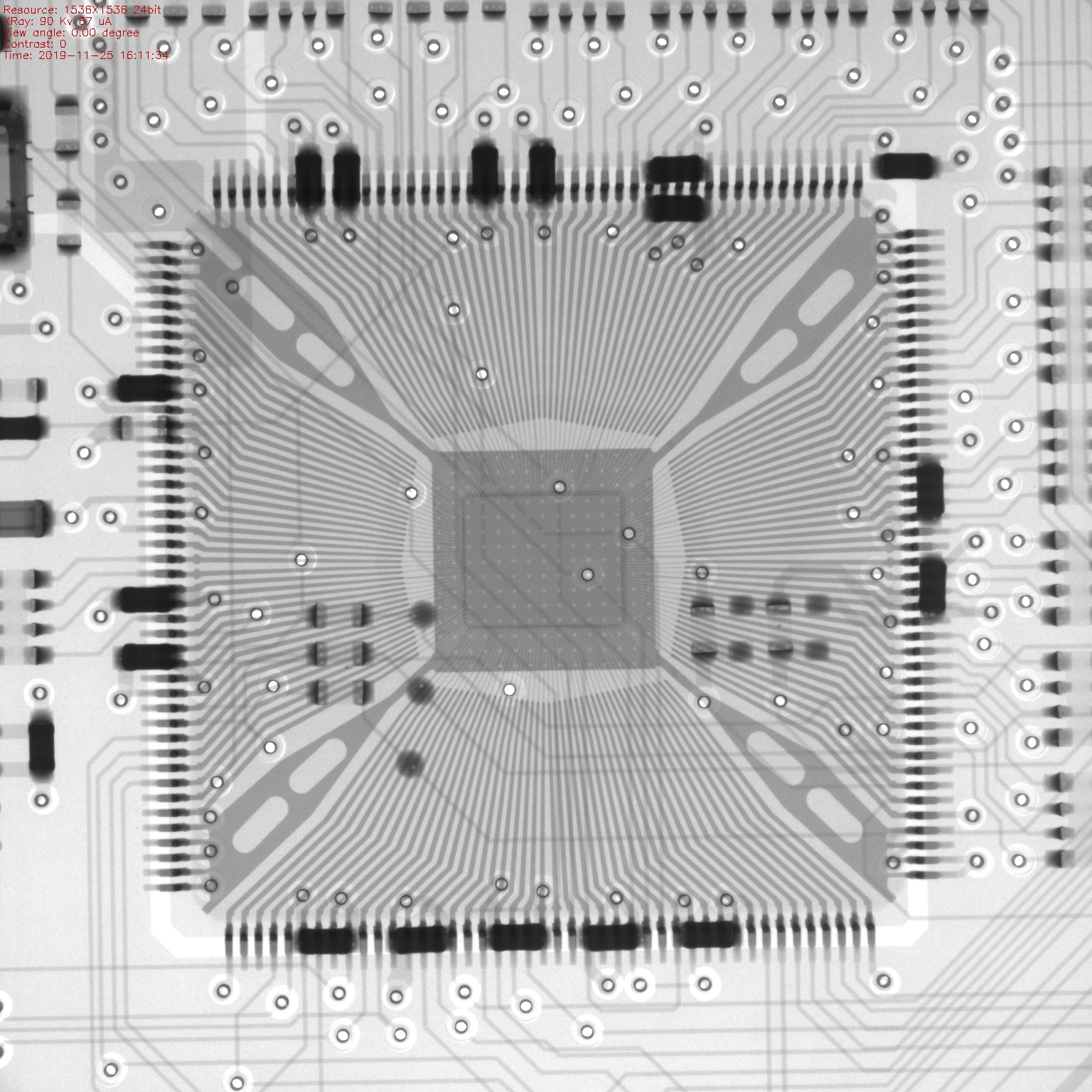

- High resolution imaging

- High accurate and efficiency

- Maintenance-free

- ISO 9001

- CE / ROHS

- X-Ray Radiation Level ≤1μSv/h

Publicity List of Radiation Safety Permits in Shenzhen

According to the “Regulations on the Safety and Protection of Radioisotope and Radiation Devices” Order No. 449 of the State Council of the People’s Republic of China, Entities that produce, sell and use radioisotopes and radiation devices shall obtain licenses in accordance with regulations.

Frequently Asked Questions

X-ray inspection is a non-destructive method of detecting defects or foreign objects in products or packaging by passing X-rays through the item being inspected and analyzing the resulting image.

X-ray inspection systems can be used to inspect a wide range of products, including food and beverage packaging, pharmaceuticals, electronics, and automotive parts.

X-ray inspection works by passing X-rays through the product or package being inspected. The X-rays are absorbed differently by different materials, allowing the system to detect defects, foreign objects, or other anomalies.

X-ray inspection can help ensure product quality and safety by detecting defects, foreign objects, or other issues that could affect product performance or consumer health. It can also help reduce waste and improve production efficiency by identifying and removing defective products from the production line.

Yes, X-ray inspection systems can be customized to fit the specific needs of different production lines, including the size and shape of products being inspected.

The cost of X-ray inspection systems can vary depending on the complexity of the system and the specific needs of the production line. However, the benefits of increased product quality and safety, reduced waste, and improved efficiency can make them a worthwhile investment for many companies.