ISO Certified | Compliant With Local Radiation Safety Policy

Powerful and Safe-to-use X-Ray Inspection System

- ISO 9001

- CE / ROHS

- X-Ray Radiation Level ≤1μSv/h

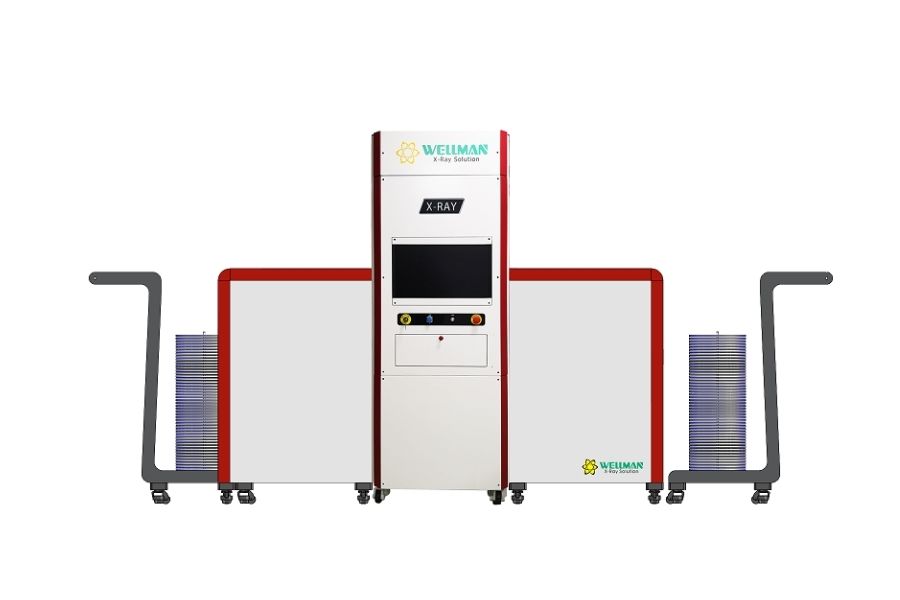

In-line Full Automatic X-ray Parts Counter IL-1000

IL-1000 is an advanced in-line x-ray parts counter/reel counter system, and it can provide fast and accurate component counting and help to make better inventory control, which saves your time and labor cost in component counting and management.

IL-1000 uses advanced x-ray technology or accurate and fast counting of SMD reels. It can count multiple reels at once, saving time and increasing productivity. IL-1000 can store and retrieve count data for future reference. Besides, it can be connected to a computer for data management and analysis.

Features

1. Oxford Instruments 80kV X-ray tube, longer lifetime, maintenance-free.

2. IRay 17” super definition digital flat panel detector (FPD).

3. Ultrafast counting, each reel only needs about 10s.

4. Support max 17” (430mm) reel or tray with moisture barrier bags.

5. Permanently updated AI deep learning algorithm for free, support connecting MES, ERP, WMS, and other management systems.

6. No need to input the material in the factory in advance, direct use.

7. Compared with the traditional parts counter, it greatly improves the efficiency, accuracy, saves manpower and shortens the time of material delivery and warehousing.

8. Support work order number function and counting record query & statistics.

High Speed and High Accuracy - X-ray parts counter IL-1000

| Reel size | Parts size | Quantity | Repeat Accuracy | Speed |

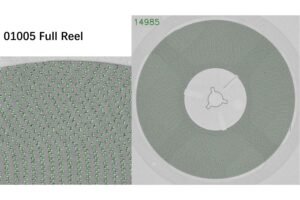

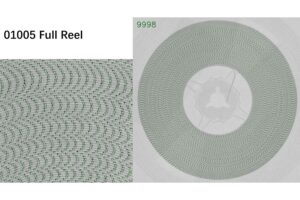

| 7” (180mm) | 01005 | 10000 | 99.98% | 9-10s |

| 7” (180mm) | 0201 | 10000 | 99.99% | 9-10s |

| 7” (180mm) | 0402 | 10000 | 99.99% | 9-10s |

| 7” (180mm) | 0603 | 5000 | 99.99% | 8-10s |

| 10” (254mm) | 1206 | 5000 | 99.99% | 9-10s |

| 15” (380mm) | 1206 | 10000 | 99.99% | 10-12s |

Specifiactions

| X-ray source | Type | Integrated, microfocus |

| Brand | America Oxford | |

| Max tube voltage | 80kV | |

| Max tube current | 700μA | |

| Focal spot size | 30μm | |

| Flat panel detector | Type | Super definition digital FPD |

| Brand | IRay | |

| Effective area | 427mm*427mm | |

| Pixel size | 139μm | |

| Resolution | 3072*3072 | |

| Reel/tray counting | Max size | 17” (430mm) |

| Max thickness | 88mm | |

| Min parts size | 01005 | |

| Speed | Appr. 10s | |

| Accuracy | ≥99.98% | |

| Media type | Reel materials, tray materials with moisture-proof bag | |

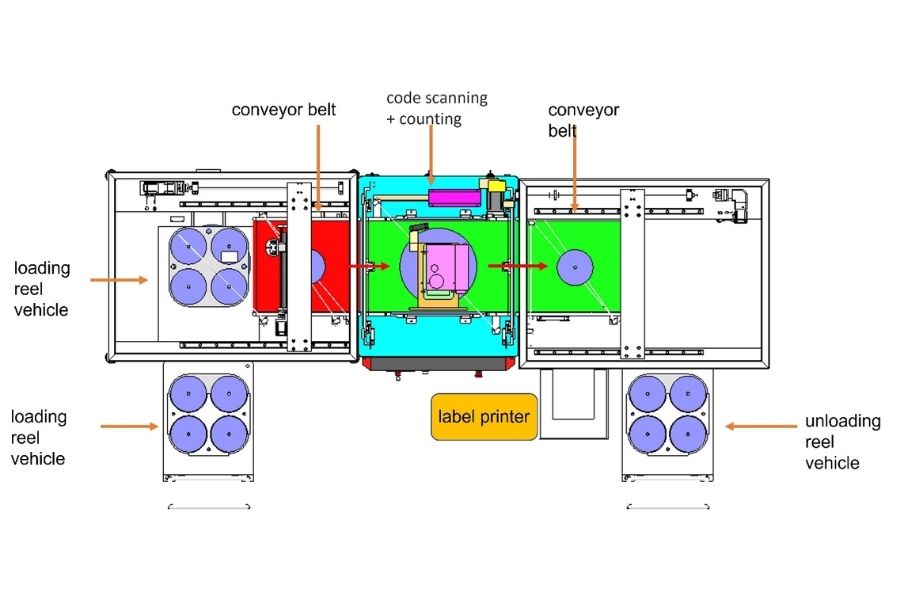

| Equipment | Dimensions | 3000mm (L) * 2000mm (W) * 2000mm (H) |

| Weight | 3000kg | |

| Power supply | AC110-220V 50/60HZ | |

| Max power | 4800W | |

| Industrial PC | I7-9700 CPU, 32G RAM, 256G SSD+4T HDD | |

| Displayer | 24” HDMI LCD | |

| Management system connection | MES, ERP etc. | |

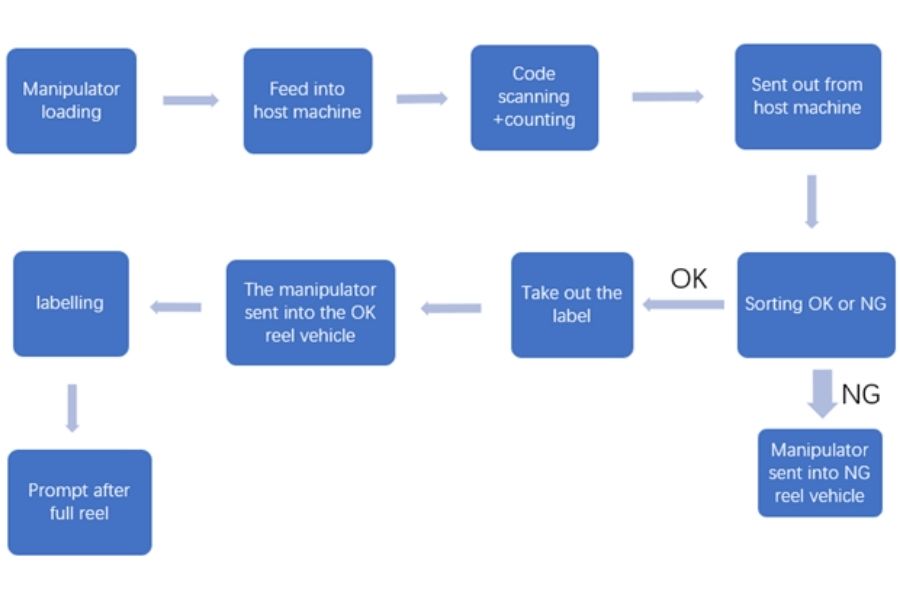

| Workflow | Loading | After the reel vehicle is pushed in, the manipulator automatically loads, supporting 7 to 15 inches of reel |

| Max loading quantity | 200 reels (7″ with 8mm thickness) | |

| Code scanning | Barcode and QR code. | |

| Reel transfer | Automatic belt transfer | |

| Labelling | Print material code and quantity automatically after counting. | |

| Unloading | The manipulator automatically put into the reel vehicle | |

| Safety | Radiation leakage | No leakage, international standard: ≤1μSv/h. |

| Back door safety interlock | Once users open the back door, X-ray tube will power off immediately. When the back door is open, users can’t turn on the X-ray. | |

| Emergency stop | In front of the operation position, press to power off. |

Working Principle

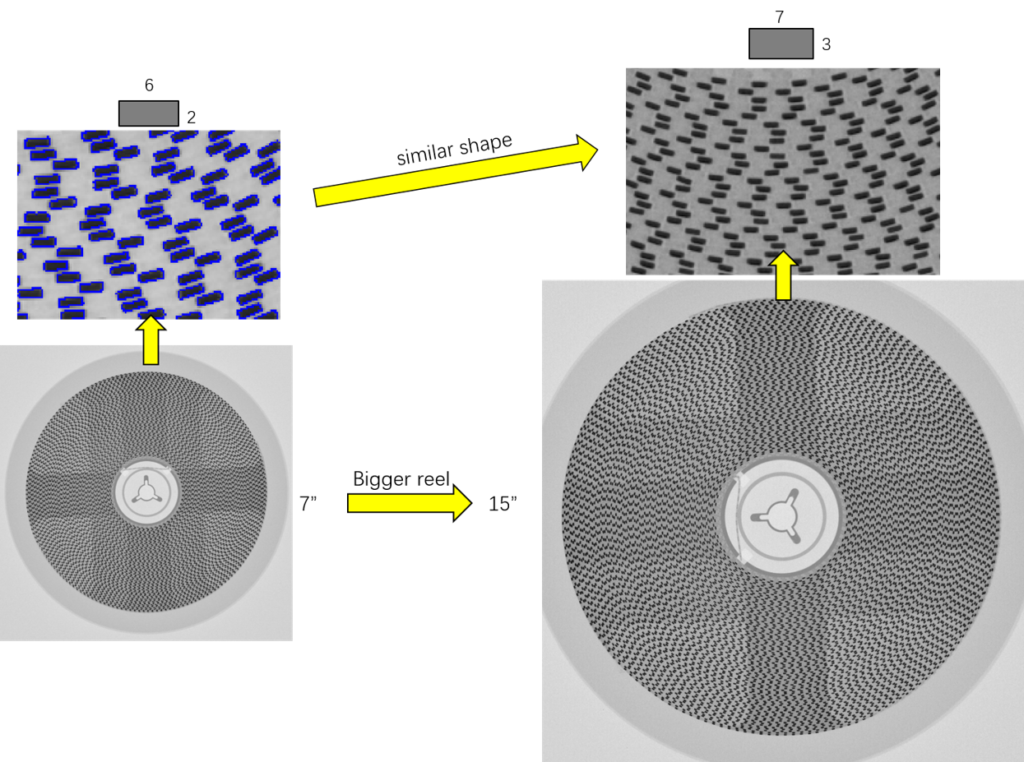

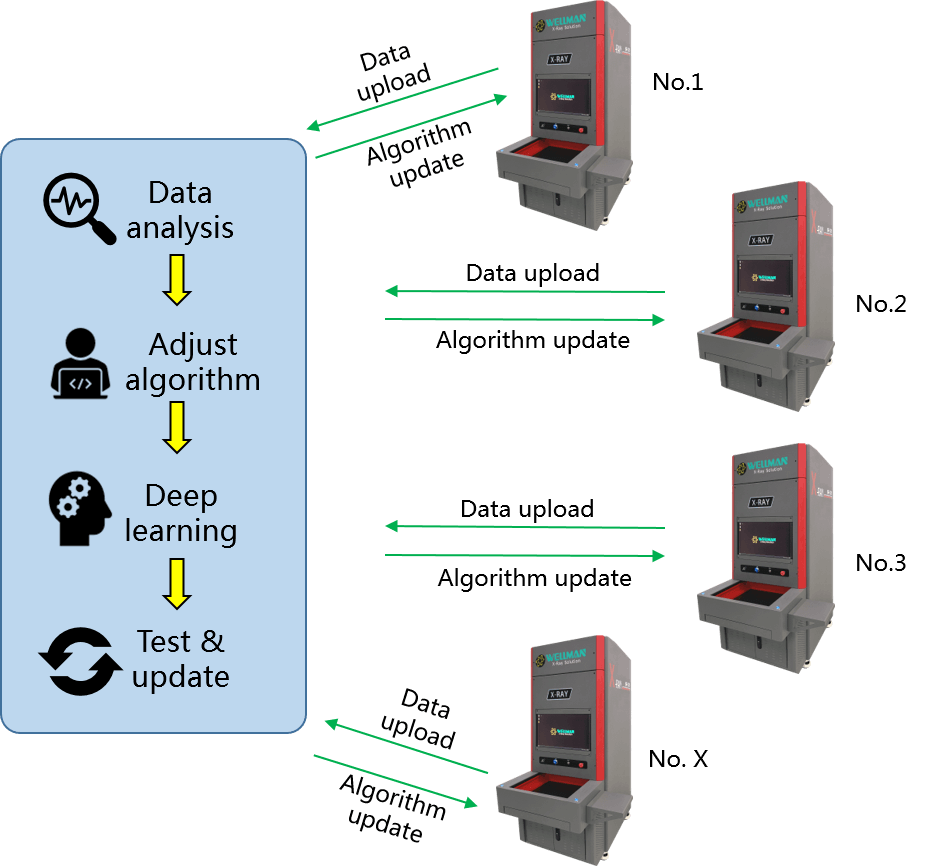

Artificial intelligence deep learning algorithm

Our counting software uses a powerful artificial intelligence deep learning algorithm. No need to bind components to algorithm, we use AI to automatically identify components and automatically apply algorithm. The algorithm can learn the counted component data, such as:

- Aspect ratio

- The angle of each corner of the component;

- Slope between components from inside to outside;

- Deformation of component images from the inside to the outside, etc.

As the number of components counting increases, the results become more and more accurate. When we need to count similar components, or larger trays, we can easily handle it.

Cloud database

Every Wellman X-ray counter can connect to our cloud database. The data and images of the machine will be uploaded to the cloud, and the machine will automatically download the latest database. Our engineers also optimize the algorithm in the background according to the images and data collected by each machine, and regularly update it to the database for customers.

Over time, the accuracy of counting will be closer to 100%, and the coverage of component types will become wider and wider. When a machine counts a new kind of component, if the data of this kind of component is stored in our database, our software can directly call the data, which brings users higher efficiency, accuracy and coverage.

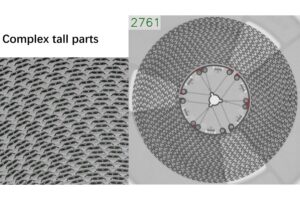

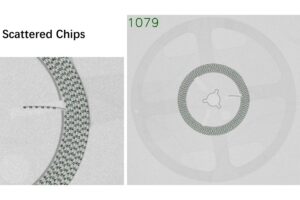

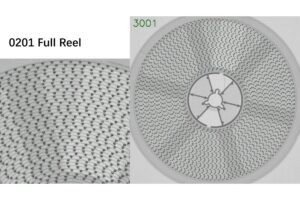

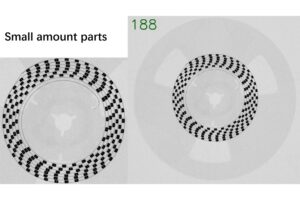

Sample Images

Application

Automaticlly counting resistors, capacitors, inductors, crystals, LED, diodes, transistors, and other multi-pin IC.

Radiation Safety Guarantee

All X-ray machines manufactured by Wellman meet the requirement of FDA-CDRH Regulation CFR 21 1020.40 Subchapter J for cabinet x-ray systems. The FDA – CDRH standard for cabinet x-ray systems states that radiation emission shall not more than. 5millirem a /hr.2″from any external surface. Our machines (X-Ray Radiation Level <1μSv/h ) are typically 5-10 times less emission than the standards, so there are no radiation concerns for operators.

| Operation Safety | |

|---|---|

| Radiation Leakage | No leakage, international standard: ≤1μSv/h |

| Lead Glass Observation Window | Transparent lead glass window to shields radiation, safe to observe the inner status. |

| Window and Back Door Safety Interlock | Once open the window or back door, the X-ray tube will power off immediately. When the window or back door is open, the operator cannot turn on the X-ray. |

| Electromagnetic Safety Switch | Once the X-ray is on, the window will automatically lock, so the operator can’t open the window. |