ISO Certified | Compliant With Local Radiation Safety Policy

Powerful and Safe-to-use X-Ray Inspection System

- ISO 9001

- CE / ROHS

- X-Ray Radiation Level ≤1μSv/h

90KV Hamamatsu Microfocus X-ray Tube(110KV,130KV optional)

The Hamamatsu Microfocus X-ray sources were developed specifically for X-ray non-destructive inspection. These X-ray sources use an X-ray tube with a small focal spot of several micro-meters to 10 micro-meters, capable of producing a clear X-ray image even at a high magnification. The RS-232C interface is provided as a standard feature, allowing automatic operation by external control.

The X-ray tube has an air-cooled and hermetically sealed structure, and is integrated with its high voltage power supply for easy handling. (High voltage cables are not required.)

Model list

Hamamatsu L11831-01 Hamamatsu L9631

Hamamatsu L9181-02 Hamamatsu L9181-05

Hamamatsu L12161-07

Hamamatsu L11831

Hamamatsu L9181

Hamamatsu L10941

Hamamatsu L10941-01

Hamamatsu L10941-05 Hamamatsu L12531

Hamamatsu L14351-02

Hamamatsu V10905P

Hamamatsu V10905P-01

Hamamatsu V7227P-03

Features

- Focal Spot Size: 5 μm, enables sharp and clear X-ray images even at a high magnification

- Easy Handling: fully operable from an external PC

- One package of a sealed type X-ray tube, a high-voltage power supply and a control function

Specifiactions

| GENERAL | ||

|---|---|---|

| Parameter | Description / Value | Unit |

| Input Voltage (DC) | 24 | V |

| Power Consumption (Max.) | 96 | W |

| Operating Ambient Temperature | +10 to +40 | ℃ |

| Storage Temperature | 0 to +50 | ℃ |

| Operating and Storage Humidity | Below 85 (No Condensation) | % |

| Weight | Approx. 9 | kg |

| Conformance Standards | CE (EMC: IEC 61326-1, Group1, Class A) | — |

| Operation | Continuous | — |

| High Voltage Power Supply | Built-in | — |

| X-RAY TUBE | ||

| Parameter | Description / Value | Unit |

| X-ray Tube | Sealed Type | — |

| X-ray Tube Cooling Method | Convection Cooling | — |

| X-ray Tube Window Material / Thickness | Beryllium / 150 | μm |

| Target Material | Tungsten | — |

| Tube Voltage Operational Range | 40 to 90 | kV |

| Tube Current Operational Range 1 | 10 to 200 (8 W Max.) | μA |

| Maximum Output | 8 | W |

| X-ray Focal Spot Size | 7 (5 μm at 4 W) | μm |

| X-ray Beam Angle (Coned) | 30 | degrees |

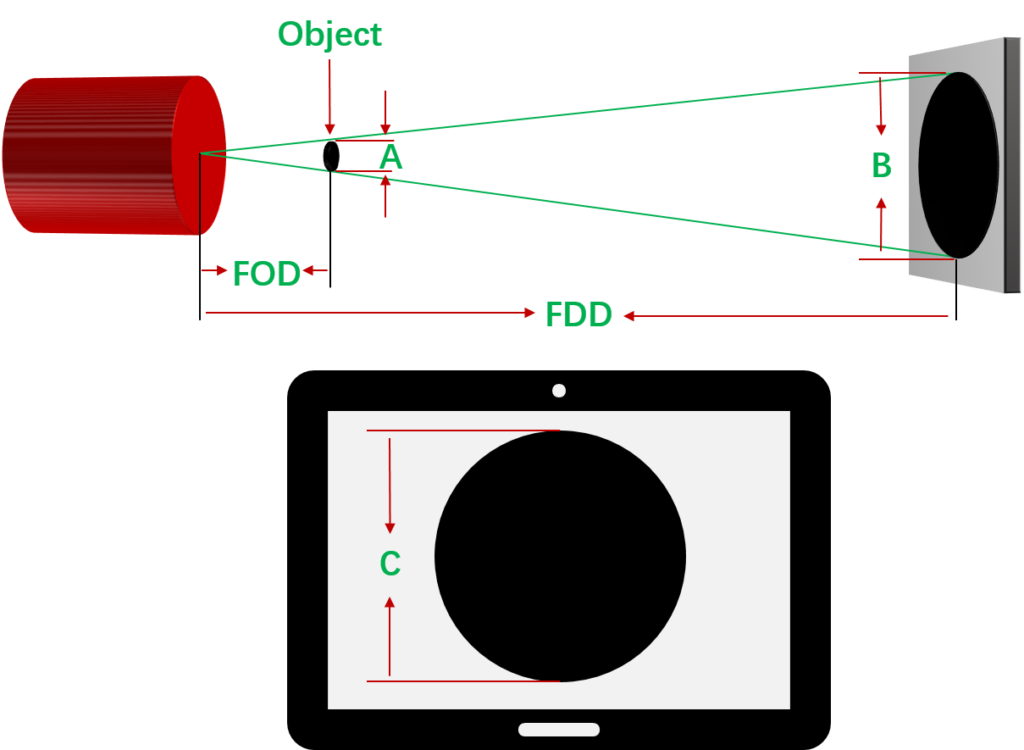

| Focus to Object Distance (FOD) | 11 | mm |

| X-RAY CONTROL PART | ||

| Parameter | Description | Unit |

| Function | Tube Voltage and Tube Current Preset / Auto Warm-up | — |

| Protection | Interlock | — |

| External Control | RS-232C | — |

| Applicable OS | Windows® 2000 Professional, XP Professional | — |

| Computer Operating Conditions | CPU: Intel Pentium or Higher, Memory: 64 MB or More | — |

Working Principle

Application

- Non-destructive Inspection

- X-ray CT

- In-line X-ray Inspection

Suitable for semiconductor , batteries , small metal casting, electronics cables and connectors, 3d printing module, medical device and parts inspection.

Radiation Safety Guarantee

All X-ray machines manufactured by Wellman meet the requirement of FDA-CDRH Regulation CFR 21 1020.40 Subchapter J for cabinet x-ray systems. The FDA – CDRH standard for cabinet x-ray systems states that radiation emission shall not more than. 5millirem a /hr.2″from any external surface. Our machines (X-Ray Radiation Level <1μSv/h ) are typically 5-10 times less emission than the standards, so there are no radiation concerns for operators.

| Operation Safety | |

|---|---|

| Radiation Leakage | No leakage, international standard: ≤1μSv/h |

| Lead Glass Observation Window | Transparent lead glass window to shields radiation, safe to observe the inner status. |

| Window and Back Door Safety Interlock | Once open the window or back door, the X-ray tube will power off immediately. When the window or back door is open, the operator cannot turn on the X-ray. |

| Electromagnetic Safety Switch | Once the X-ray is on, the window will automatically lock, so the operator can’t open the window. |