ISO Certified | Compliant With Local Radiation Safety Policy

Fast and Accurate X-Ray Component Counter System

- High resolution imaging

- High accurate and efficiency

- Maintenance-free

- ISO 9001

- CE / ROHS

- X-Ray Radiation Level ≤1μSv/h

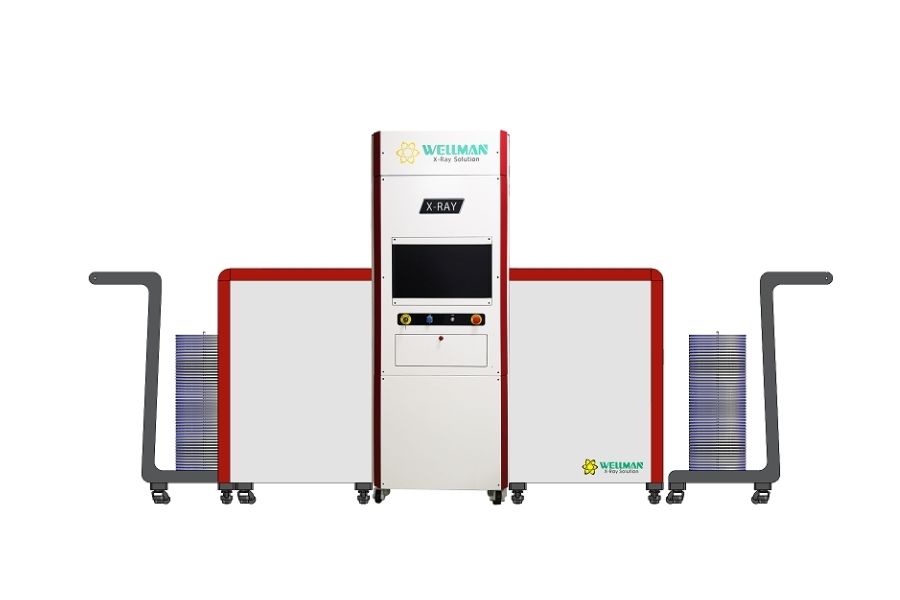

X-Ray Component Counter

One of Wellman’s core businesses is the design and manufacture of high-precision X-ray component counters. Leveraging decades of expertise in X-ray inspection technologies, Wellman produces reliable and accurate component counters that enable Electronics Manufacturing Services (EMS) companies to improve their parts inventory management and reduce costs. Wellman’s X-ray component counters help EMS clients detect miscounts and missing components during incoming inspection of parts and components used in the assembly of printed circuit boards and electronic devices. By identifying discrepancies early, Wellman’s solutions help EMS companies avoid costly issues related to improper inventory levels and product defects.

In-line Full Automatic X-ray Parts Counter IL-1000

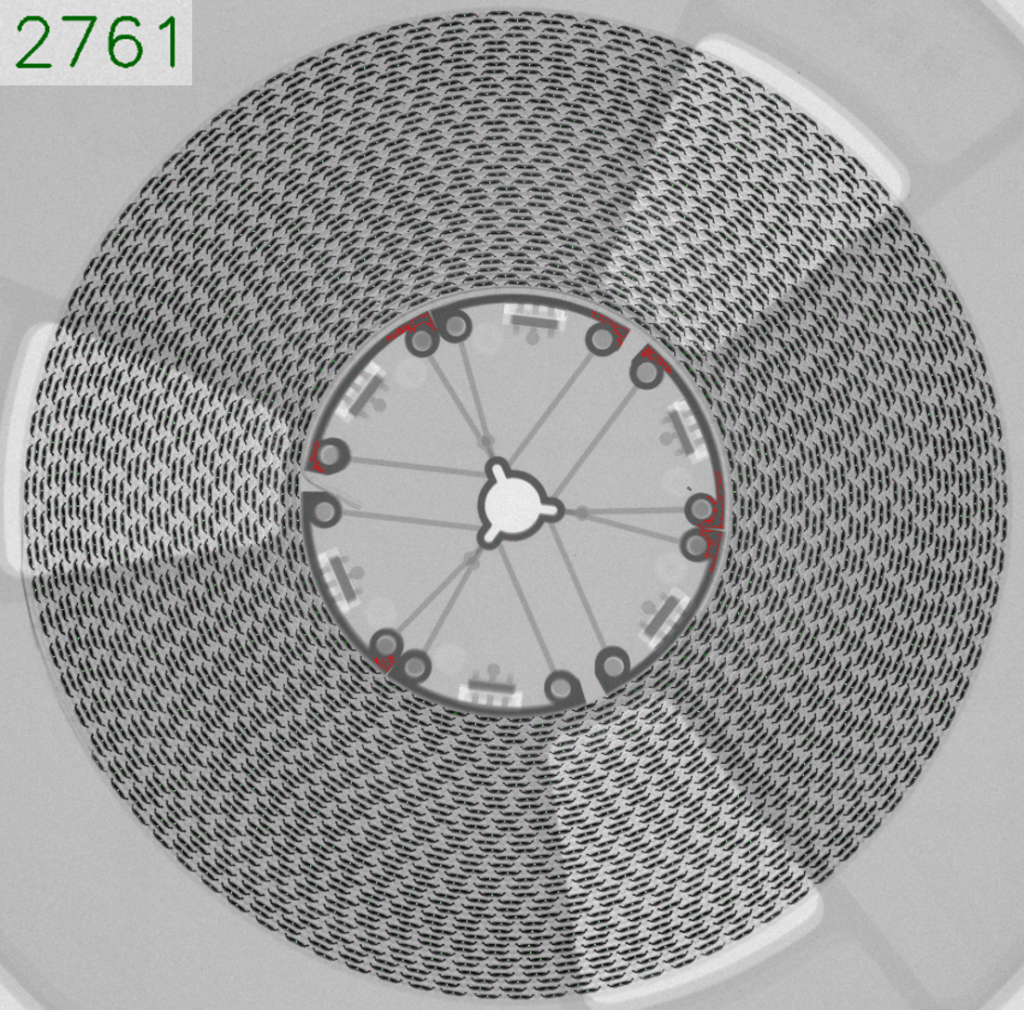

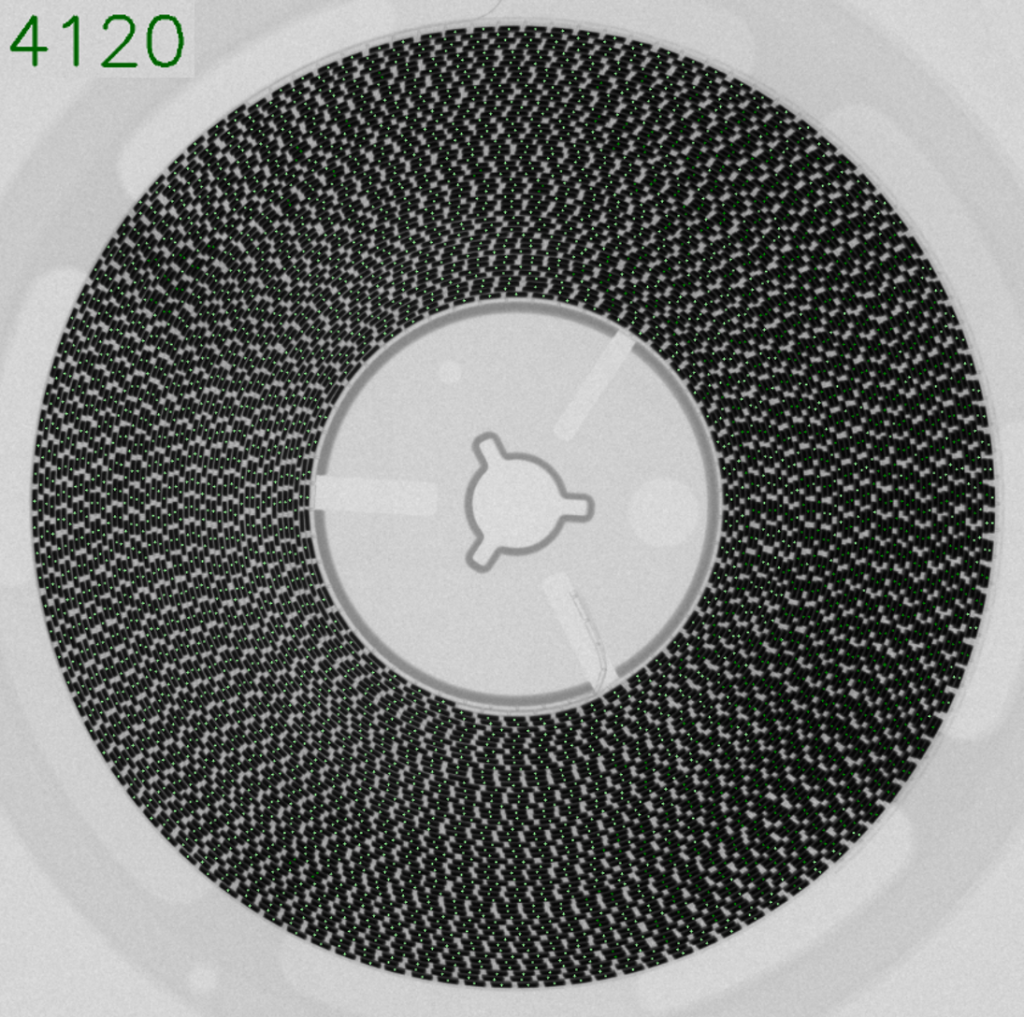

IL-1000 is an advanced in-line x-ray parts counter/reel counter system, and it can provide fast and accurate component counting and help to make better inventory control, which saves your time and labor cost in component counting and management.

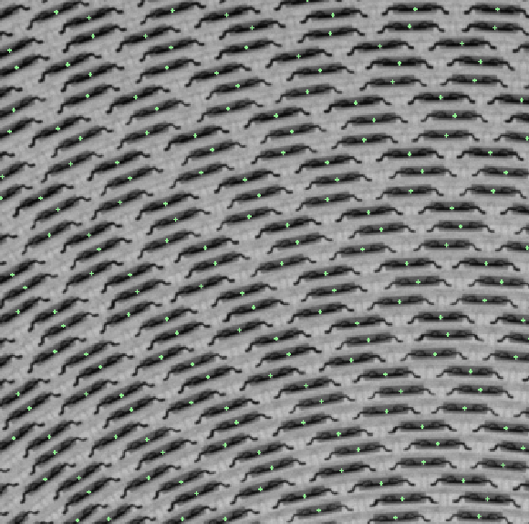

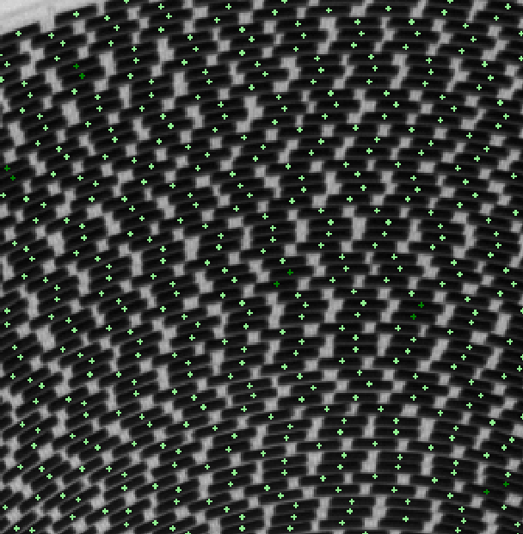

Manual component counting for surface mount devices (SMDs) is tedious, time-consuming, and prone to human error. X-ray component counting machines offer a faster, more accurate, and automated alternative. These advanced systems leverage X-ray imaging technology to rapidly identify, count, and inspect SMD components.

A key advantage is throughput – X-ray machines can process thousands of components every 10 seconds, far outpacing any manual process. They ensure accurate tallies by automatically detecting overlapping and misaligned parts that could be missed by the naked eye. X-ray counting is non-destructive and non-contact, preventing potential damage during handling.

X-ray component counters integrate seamlessly with materials management software, enabling automated record keeping and traceability. Data integrity is another major benefit, as X-ray analysis positively identifies materials to prevent counterfeit components from infiltrating production lines.

For electronics manufacturers prioritizing quality, efficiency and traceability, X-ray component counting machines are an essential asset. The accuracy, speed and insight they provide is unmatched compared to manual visual counting methods.