Table of Contents

ToggleDefinition of Focal Spot Size

The focal spot size, also known as the effective focal spot size, is a crucial parameter in X-ray imaging systems. It refers to the area on the anode target of an X-ray tube from which the X-rays are generated. The focal spot size directly impacts the spatial resolution and image quality of the resulting X-ray images.

Importance in Imaging Applications

The focal spot size plays a significant role in various imaging applications, including medical diagnostics, non-destructive testing, and scientific research. Smaller focal spot sizes generally lead to improved image resolution and clarity, enabling better visualization of fine details and structures. However, decreasing the focal spot size also reduces the heat loading capacity of the X-ray tube, potentially limiting its power output.

Basics of X-Ray Tubes

Components of an X-ray Tube

To understand the concept of focal spot size, it’s essential to have a basic understanding of the components of an X-ray tube. An X-ray tube consists of a vacuum-sealed glass or metal envelope containing a cathode and an anode. The cathode emits electrons, which are accelerated towards the anode by a high-voltage potential difference.

Principles of X-ray Generation

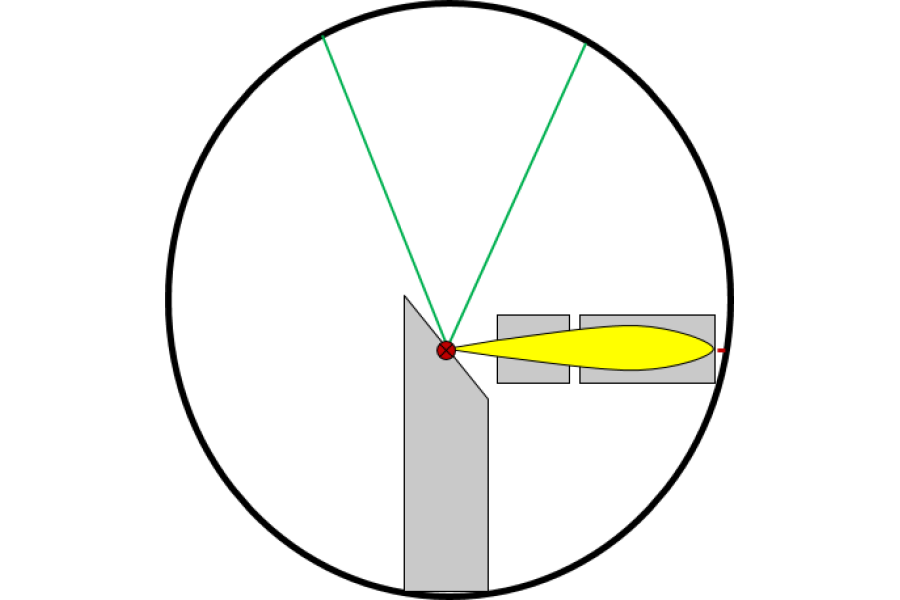

When the high-energy electrons strike the anode target, they interact with the target material, causing the emission of X-rays. The area on the anode where the electrons strike and generate X-rays is known as the focal spot. The size of this focal spot directly influences the spatial resolution and other characteristics of the resulting X-ray beam.

Factors Affecting Focal Spot Size

Electron Beam Focus

One of the primary factors influencing the focal spot size is the focus of the electron beam. The cathode assembly in an X-ray tube plays a crucial role in controlling the electron beam and determining its focus. Various techniques, such as electrostatic or magnetic focusing, are employed to concentrate the electron beam onto a small area on the anode target, thereby reducing the focal spot size.

Target Material and Angle

The material composition and angle of the anode target also affect the focal spot size. Different target materials have varying properties, such as thermal conductivity and melting point, which can influence the size of the focal spot. Additionally, the angle at which the electron beam strikes the target can impact the effective focal spot size and the distribution of X-ray emission.

X-ray Tube Design

The overall design of the X-ray tube, including the geometry and dimensions of the cathode and anode assemblies, can significantly influence the focal spot size. Manufacturers employ various engineering techniques and design optimizations to achieve desired focal spot sizes for specific applications.

Effects of Focal Spot Size

Spatial Resolution

The focal spot size directly impacts the spatial resolution of the X-ray imaging system. A smaller focal spot size generally results in better spatial resolution, allowing for the visualization of finer details and structures in the imaged object. This is particularly important in applications such as medical imaging, where high spatial resolution is crucial for accurate diagnosis and treatment planning.

Image Sharpness and Clarity

In addition to spatial resolution, the focal spot size also affects the overall sharpness and clarity of the X-ray images. A larger focal spot size can lead to blurring and reduced image quality, especially when imaging small or fine structures. This can be particularly problematic in applications like non-destructive testing, where the ability to detect and characterize defects or flaws is critical.

Heat Loading Capacity

While a smaller focal spot size generally improves image quality, it also reduces the heat loading capacity of the X-ray tube. The concentrated electron beam on a smaller area can lead to increased heat generation, potentially limiting the power output and duty cycle of the X-ray tube. This trade-off between focal spot size and heat loading capacity must be carefully considered when selecting an X-ray tube for a specific application.

Measurement Techniques

Slit Camera Method

One commonly used technique for measuring the focal spot size is the slit camera method. In this method, a narrow slit is placed between the X-ray tube and a detector, allowing only a thin slice of the X-ray beam to pass through. By analyzing the resulting image or intensity profile, the focal spot size can be estimated based on the geometric principles of image formation.

Star Pattern Method

Another technique for measuring focal spot size is the star pattern method. This method involves placing a star-shaped aperture or mask between the X-ray tube and the detector. The resulting image pattern, consisting of overlapping line pairs, is analyzed to determine the focal spot size based on the geometric properties of the pattern and the level of blurring observed.

Other Techniques

Several other techniques are also employed for measuring focal spot size, including the pinhole camera method, the knife-edge method, and the wire method. These techniques rely on different principles and geometric configurations to estimate the effective focal spot size, each with its own advantages and limitations.

Applications

Medical Imaging

In the field of medical imaging, focal spot size plays a crucial role in ensuring high-quality diagnostic images. Smaller focal spot sizes are generally preferred for applications such as mammography, where the visualization of fine details is essential for early detection and accurate diagnosis of breast cancer. However, in some applications like radiography or fluoroscopy, a larger focal spot size may be used to accommodate higher power requirements and longer exposure times.

Industrial Radiography

In industrial radiography, the focal spot size is an important consideration for non-destructive testing and inspection of materials and components. Smaller focal spot sizes are typically preferred for high-resolution imaging and detection of small defects or flaws. However, larger focal spot sizes may be used in applications where penetration power and throughput are more important than spatial resolution.

Scientific Research

In scientific research applications, such as X-ray crystallography, small-angle X-ray scattering (SAXS), and X-ray microscopy, the focal spot size plays a crucial role in achieving high spatial resolution and enabling detailed characterization of materials and structures at the microscopic or nanoscopic scale.

Trends and Future Developments

Micro-focus X-ray Tubes

As the demand for higher spatial resolution and improved image quality continues to grow, the development of micro-focus X-ray tubes has become an area of active research and development. These tubes feature exceptionally small focal spot sizes, often in the range of a few micrometers or even sub-micrometer sizes. Micro-focus X-ray tubes are finding applications in various fields, including materials science, nanotechnology, and advanced medical imaging techniques.

Advances in X-ray Source Technology

In addition to traditional X-ray tubes, emerging technologies such as liquid metal jet X-ray sources and compact synchrotron light sources are paving the way for new possibilities in X-ray imaging and analysis. These advanced X-ray sources offer unique advantages, including improved brightness, coherence, and the potential for even smaller effective focal spot sizes, enabling unprecedented spatial resolution and imaging capabilities.

Conclusion

The focal spot size is a critical parameter in X-ray imaging systems, directly influencing the spatial resolution, image quality, and heat loading capacity of the X-ray tube. Understanding the factors that affect focal spot size, measurement techniques, and its impact on various applications is essential for optimizing X-ray imaging systems and achieving desired performance goals. As technology continues to advance, the development of micro-focus X-ray sources and emerging X-ray source technologies hold promising prospects for pushing the boundaries of spatial resolution and enabling new frontiers in X-ray imaging and analysis.

FAQs

Q1: What is the typical range of focal spot sizes in medical X-ray tubes?

A1: In medical X-ray tubes, the focal spot size can range from a few hundred micrometers (e.g., 0.3 mm) for general radiography to less than 50 micrometers for specialized applications like mammography.

Q2: How does the focal spot size affect the image quality in non-destructive testing?

A2: In non-destructive testing, a smaller focal spot size generally improves the spatial resolution and the ability to detect and characterize smaller defects or flaws. However, a larger focal spot size may be preferred for applications requiring higher penetration power or throughput.

Q3: Can the focal spot size be adjusted in an X-ray tube?

A3: In some X-ray tubes, the focal spot size can be adjusted by changing the focus of the electron beam or the angle of the anode target. However, in most cases, the focal spot size is a fixed property determined by the design and manufacturing of the X-ray tube.

Q4: What are the challenges associated with reducing the focal spot size in X-ray tubes?

A4: As the focal spot size decreases, the heat loading capacity of the X-ray tube also decreases, limiting the power output and duty cycle. Additionally, manufacturing and aligning the components to achieve extremely small focal spot sizes can be technically challenging and costly.

Q5: Are there alternative techniques to improve spatial resolution besides reducing the focal spot size?

A5: While reducing the focal spot size is a direct way to improve spatial resolution, other techniques such as advanced reconstruction algorithms, geometric magnification, and the use of high-resolution detectors can also contribute to enhancing the overall spatial resolution of X-ray imaging systems.