ISO Certified | Compliant With Local Radiation Safety Policy

Powerful and Safe-to-use X-Ray Inspection System

- ISO 9001

- CE / ROHS

- X-Ray Radiation Level ≤1μSv/h

Labeling Machine

LM-1000 is a device that converts the supplier barcode into the internal code of the factory, based on the image algorithm, compatible with the supplier template, helps reduce human error, improves the efficiency of label change, does not need manual entry, the software automatically identifies and matches, reduces manual input errors, can be connected to MES and other management systems to achieve material management and traceability.

Features

- Automate incoming reel labeling process, greatly improve the efficiency of incoming material warehousing.

- Simplify the info input process,avoid human error.

- Automatically matches templates and automatically scans after recognizing the reel producer.

- Equipped with character recognition function instead of manual input.

- Support four 7” reels at a time.

- Users can intervene at any time to change the label info.

- Support connecting MES, ERP, WMS, and other management systems, easier to manage and trace.

- Easy and quick to operate, only needs one hour for training.

Equipment Parameter

Camera | Pixel | 20 million |

Light source | Brightness adjustable | |

Operating platform | Table size | 430*430mm |

Operating height | 870mm | |

Max reel | 17” | |

Material | Explosion-proof tempered glass | |

Function | Producer management | Automatically recognize reel producer and matches templates |

Auto code scanning | Barcode and QR code | |

Character recognition | Letters and numbers | |

Manual input info | Yes | |

Print label | Print the corresponding label when picking up any reel | |

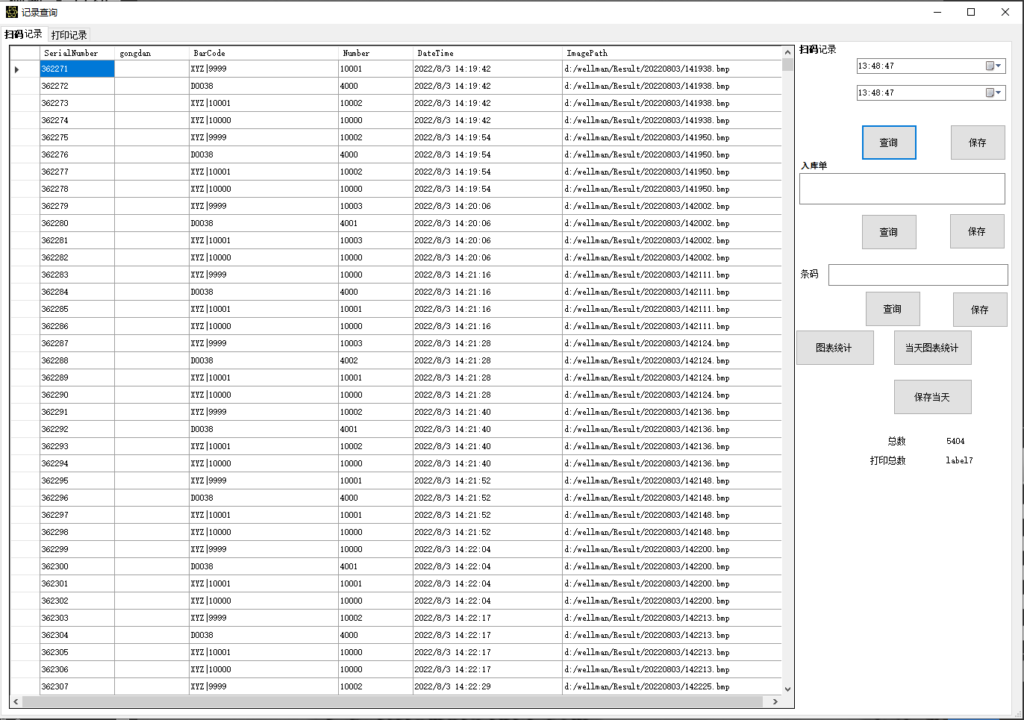

Labeling record | Inquiry by time range, work order number, automatic statistics | |

Management system connection | MES, ERP, WMS, etc. | |

Warehouse entry number | Support the function of warehouse entry number recording | |

Equipment | Dimensions | 1000mm*800mm*1600mm |

Weight | 130kg | |

Power supply | AC110-220V 50/60HZ | |

Max power | 800W | |

Industrial PC | I7 CPU, 8G RAM, 240G SSD+1T HDD | |

Displayer | 24” HDMI displayer | |

Printer | ZEBRA ZD888CR micro industrial printer |

Software Interfaces

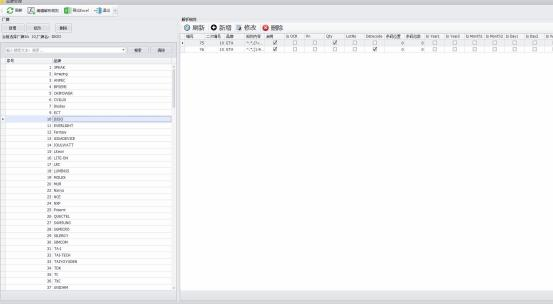

Producer management

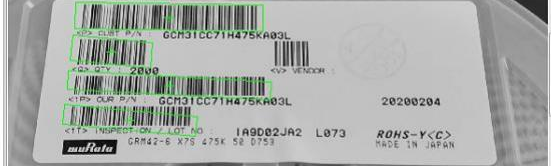

Code scanning

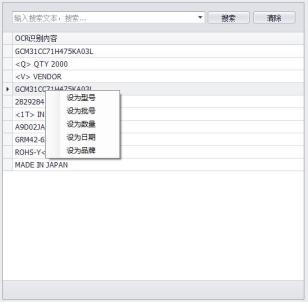

Character recognition

Database query

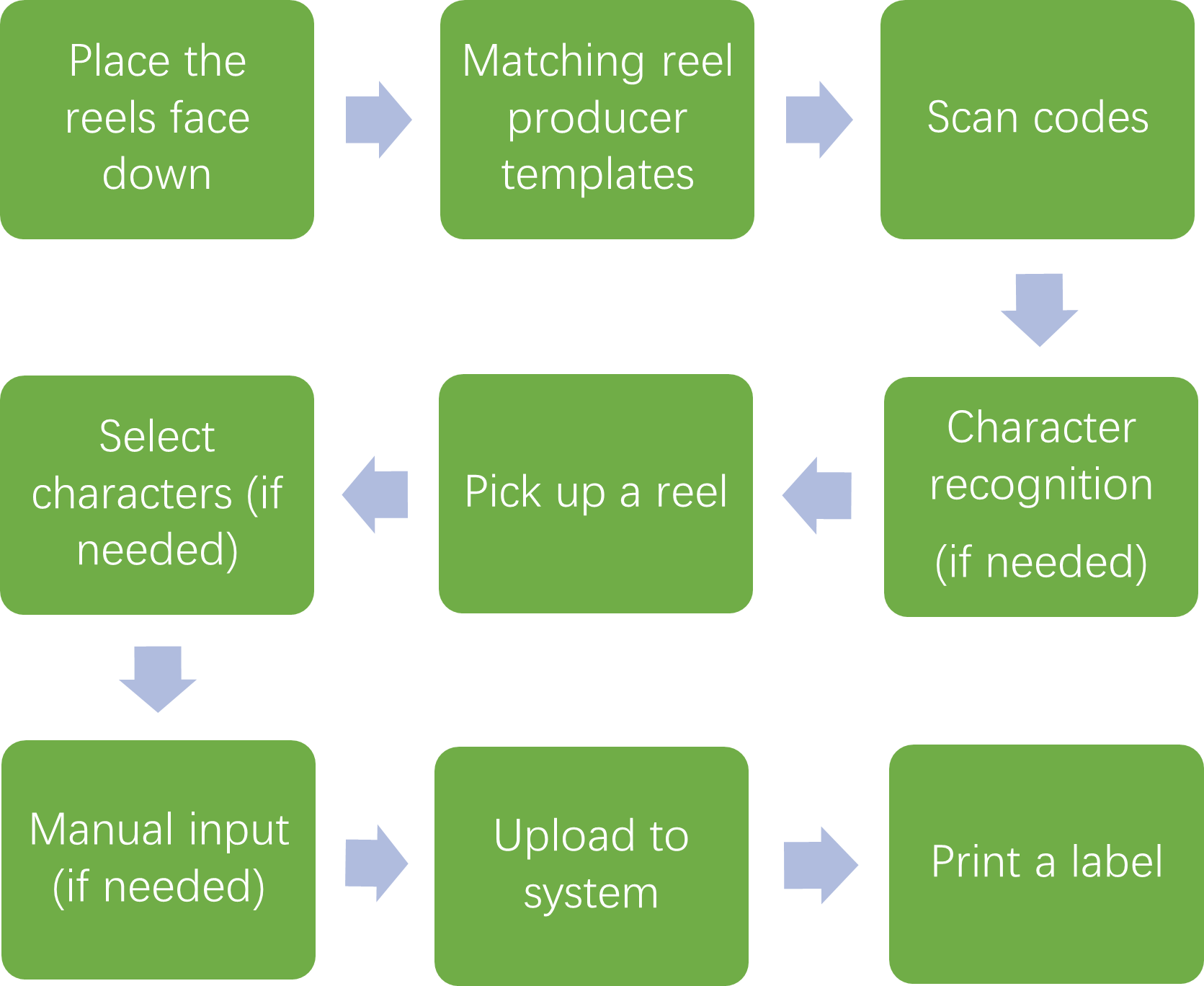

Workflow