The Application and Challenges of X-ray Testing in the Lithium Battery Industry

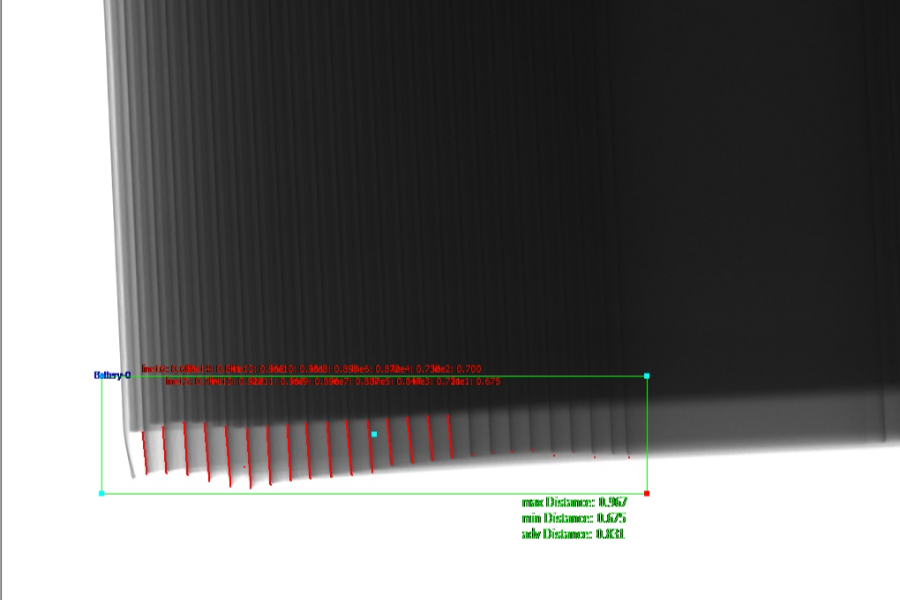

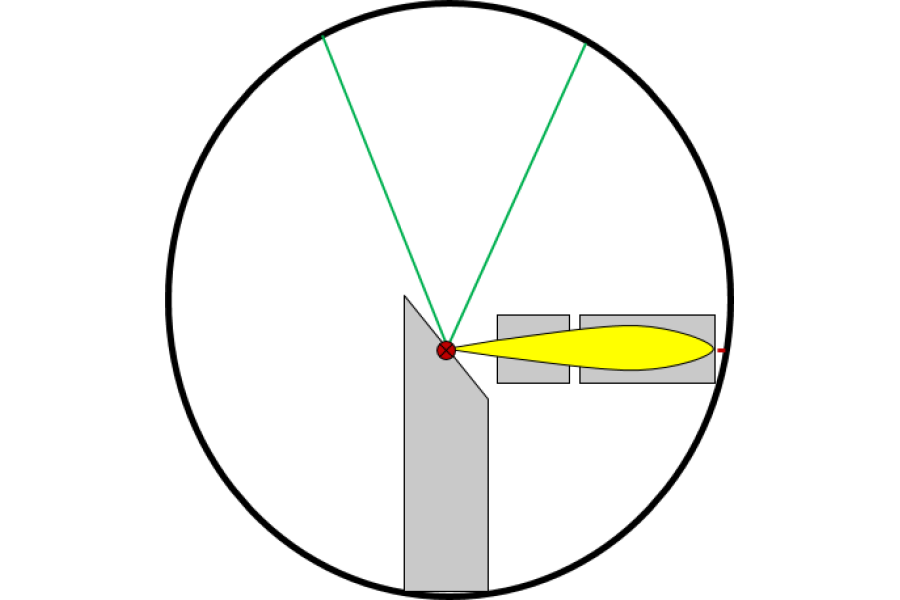

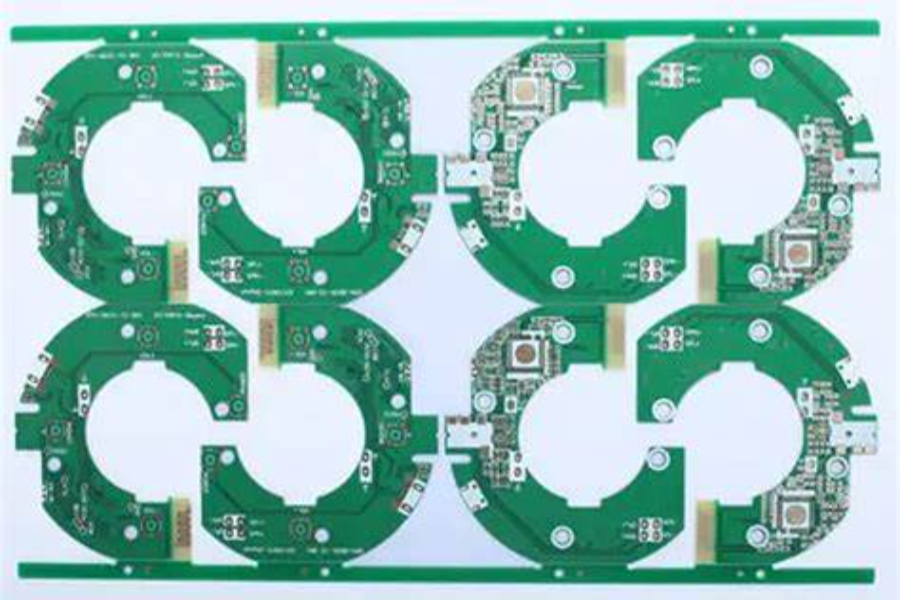

Intro Importance of lithium batteries In today’s world, lithium-ion batteries have become an integral part of our lives, powering everything from smartphones and laptops to electric vehicles and energy storage systems. As the demand for these batteries continues to soar, ensuring their quality and safety has become a top priority for manufacturers. Quality control challenges […]

The Application and Challenges of X-ray Testing in the Lithium Battery Industry En savoir plus "